MakMax Plus

Explains the advantages of WMS (Warehouse Management System) and how to choose one! In-depth comparison of the latest 10 WMS products, including the company with the No. 1 market share

2024.01.23

A WMS (Warehouse Management System) can streamline logistics-related operations such as warehouse operations and inventory management, which tend to be complicated.

Since many WMS products and services have been released, some may say, “I don’t know which WMS has which functions.

In this article, in addition to the advantages of WMS and how to choose one, we compare and introduce the latest version of 10 WMS products, including the product with the No. 1 WMS market share.

What is WMS (Warehouse Management System)?

WMS stands for “Warehouse Management System,” and in Japanese it is called “Warehouse Management System.” WMS is characterized by its ability to centrally manage the flow of products and goods from the time they enter the warehouse until they are shipped.

A WMS can improve the efficiency of warehouse logistics operations in warehouses, such as receiving, shipping, and storage, and improve operations. WMS has been adopted by a wide range of industries, from retailers, wholesalers, food manufacturers, and manufacturers of industrial goods to e-commerce businesses, because it can improve the accuracy of operations.

▼The overview of WMS, its functions, and differences from core systems are explained in detail below

https://www.taiyokogyo.co.jp/blog/tentsouko/a394

Advantages of implementing a WMS (Warehouse Management System)

The following is an overview of the benefits of implementing a WMS.

Leads to more efficient warehouse operations

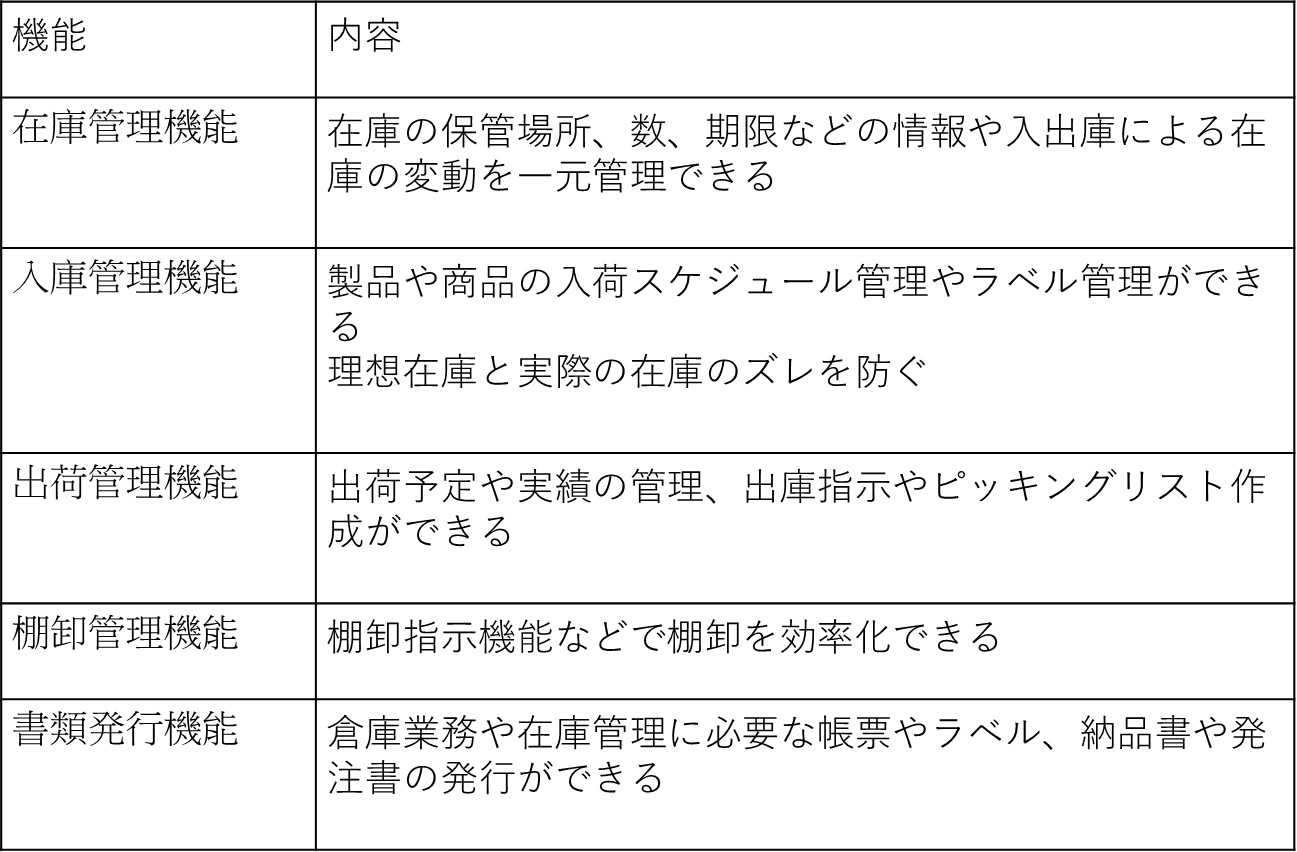

The WMS includes the following features to improve the efficiency of warehouse operations, which can easily become cumbersome.

Another advantage is that warehouse operators can work while checking product and location instructions on the terminal at hand, which greatly reduces the time spent looking for the product or item they need when entering or leaving the warehouse.

Reduce human error.

A WMS will allow you to manage your warehouse operations digitally. By digitizing tasks that are conventionally done manually or visually, some of the tasks can be automated. As a result, it is expected to reduce the workload and, in turn, reduce human error.

Furthermore, if a mistake such as an incorrect shipment should occur, the system will warn the customer, preventing mistakes from being overlooked.

Reduced costs

By simplifying and automating warehouse operations with a WMS, the number of personnel needed for warehouse operations can be reduced, and labor costs can also be reduced.

Standardizing warehouse operations will also reduce costs for staff training, since new employees and temporary staff during peak periods can begin warehouse operations immediately. It also reduces errors that directly result in costs, such as bad inventory, and can be used to reduce overall costs.

Ensure proper staffing

By standardizing work, not only veteran employees, but also part-time and casual workers, as well as newcomers and help personnel who work only during busy periods, can work at the same quality level. The WMS can also be used to track on-site progress and inventory control, making it easier to manage the entire operation and to assign appropriate personnel.

Staffing can be streamlined and wasted personnel costs can be reduced, which in turn can be appropriately allocated to departments other than warehouse operations.

Quality control of product and merchandise inventory is achieved

With a WMS, products are managed using labels and barcode scanning, making it easy to track the process from receipt to shipment. Another advantage is that if a problem occurs after shipment, such as a misdelivery or loss of an item, the movement and storage history of the item can be tracked to help resolve the problem.

In addition, the ability to monitor inventory status in real time allows the company to maintain appropriate inventory levels and prevent problems such as overstocking and shortages. As a result, the quality of goods in storage can be improved.

If a WMS enables proper inventory control and receiving/shipping operations, it can also guarantee the quality of products and goods, as well as quick shipments. As a result, customer satisfaction will be improved.

Points to keep in mind when implementing a WMS (Warehouse Management System)

A wide variety of WMSs are available as products and services from various vendors.

If you don’t introduce an appropriate WMS, you may have problems such as “the initial cost was too high and no effect was obtained,” “cost reduction and business efficiency improvement could not be achieved,” or “the system did not take root and business practices have not changed after it was introduced. Before selecting and introducing a WMS, please keep in mind the following points.

Keep abreast of the opinions and needs of the field.

Even if a WMS is implemented, if it does not match the needs of the field, the system will not take root.

For example, when a WMS is used for location management, problems may arise such as difficulty in taking pick and inspection lines due to changes in product placement, or uncertainty about how to match WMS data with actual inventory during inventory operations.

If the introduced WMS does not meet the needs of the field and, conversely, makes work more complicated, operational efficiency improvement will not be realized. Before selecting and introducing a specific system, it is important to listen carefully to the opinions of the field.

Ensure that confusion does not occur due to differences in operations between locations

When implementing a WMS, when deploying multiple warehouses, try to avoid confusion due to differences between locations as much as possible.

For example, if there is a disparity in operations between sites with and without a WMS, problems may arise, such as confusion in the field due to different tasks depending on whether a WMS is in place or not, or the inability to transfer inventory between sites.

When implementing a WMS at one site on a trial basis, it is recommended to temporarily separate it from other sites, to make it easier to coordinate with or without the WMS, and to unify operations as much as possible to avoid differences in fundamental work methods (for example, if the timing of form output has changed due to the implementation of the WMS, consider whether the timing can be matched at other sites as well). (For example, if the timing of form output has changed due to the introduction of a WMS, consider whether the timing can be adjusted at other locations as well).

Be able to coordinate with other departments involved

When a WMS is implemented, it is necessary to collaborate with the IT department, which maintains the system and reflects data, and the accounting department, which issues delivery slips and invoices through the WMS, in addition to the warehouse, which is the site of the WMS. A system should be in place to allow for coordination with the relevant departments in advance.

When a WMS is newly introduced, it is important to achieve comprehensive collaboration through the system.

Compare multiple systems

When implementing a WMS, it is important to choose from several systems and compare them. When implementing a WMS, it is important to choose from multiple systems and compare them.

Based on these considerations, the following is a step-by-step explanation of points to remember when selecting and comparing WMSs.

How to select and compare WMS (Warehouse Management Systems)

This section explains how to select and compare WMS.

Clarify the purpose of introduction and issues

The purpose of implementing a WMS differs from company to company. First, to clarify the purpose of implementing a WMS, identify the issues you wish to resolve in warehouse management. For example, you may want to thoroughly understand inventory counts, quickly grasp inventory location information, reduce personnel and costs, or improve the efficiency of warehouse operations.

Next, narrow down the functions needed in the WMS to solve the issue. Selecting and comparing the candidates from the WMS with the necessary functions will help you select a WMS that will solve your issues and achieve your objectives.

Choose one that fits your method of operation.

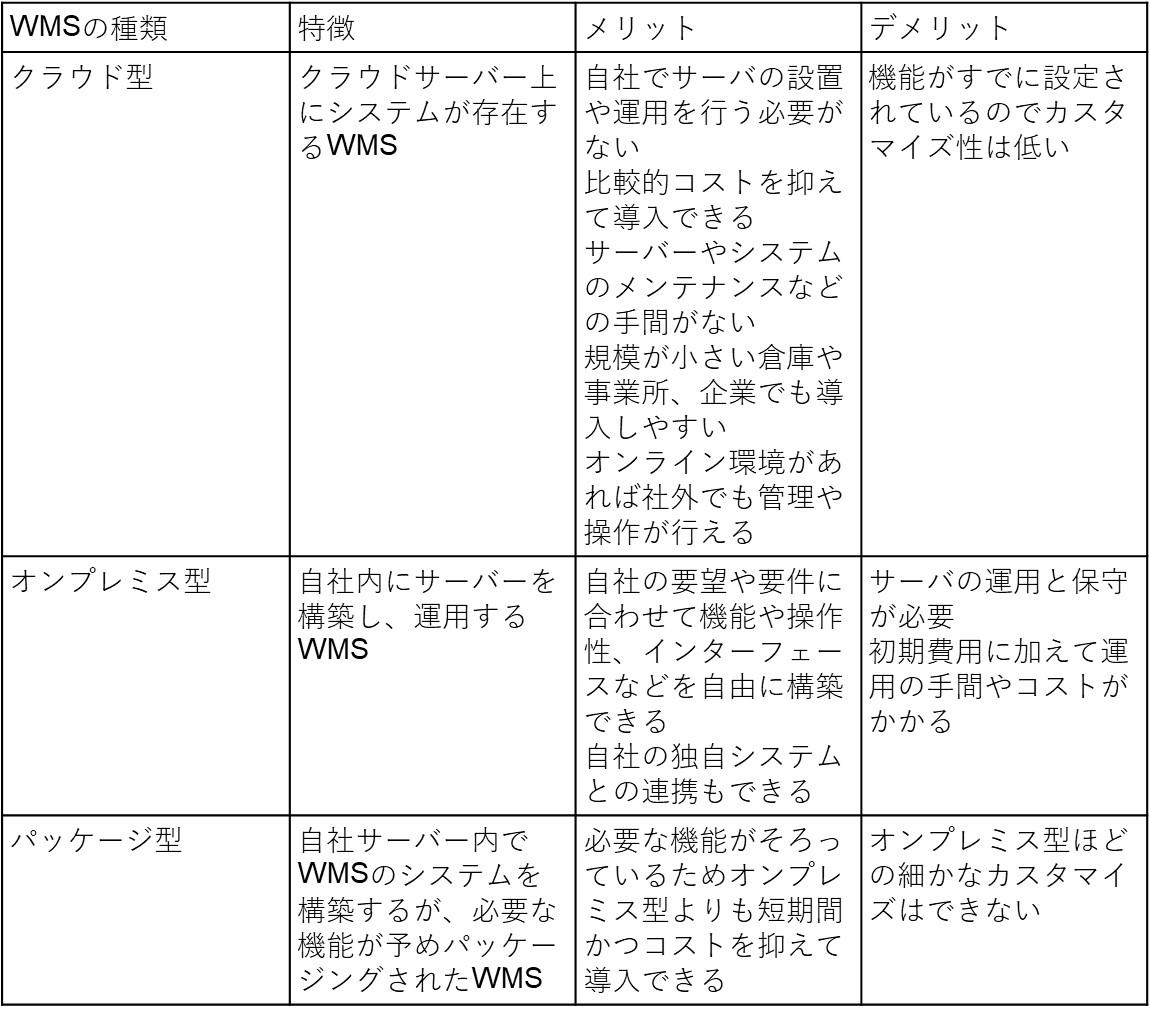

WMS can be broadly classified into the following three types: cloud-based, on-premise, and packaged.

Select the best WMS for your company based on how you envision operating it.

For example, the cloud-based WMS is designed for companies that do not have enough IT management staff, have difficulty building from scratch, or want to avoid the hassle of operations and settings. On the other hand, if the development of an ideal WMS system is more important than the cost and operational effort, the on-premise model is suitable.

Assume costs and budgets.

There are initial and running costs associated with implementing a WMS. Assume costs for server and system setup, monthly fees, maintenance, labor, and training.

Some WMSs are available free of charge, but many of the free types have limited functionality. Free plans and trials should be used only to confirm the functions and feel of the system, and should be used to select the best system for your company.

Check for linkage with core systems and sharing of information with external parties.

It is also important to select a system that can be integrated with various existing systems, such as the head office’s core system, inventory management system, sales management system, and production management system.

If information can be shared externally through the system, the time and effort required to exchange data can be greatly reduced. Please check the linkage method in conjunction with the system.

Check the target scale.

Some WMS products and services have a fixed target scale in terms of the number of warehouses and users. Therefore, depending on the target scale range, there may be insufficient functionality or data capacity, or conversely, unnecessary costs may be incurred due to the inclusion of unused functionality.

It is important to choose a product or service that fits your business, the number of warehouses you have, and the size of your operation. Check to see how many users are supported and how many locations are available.

Vendors with a good support system can provide peace of mind.

It is also important to have a good support system for the WMS system.

Depending on the vendor, the following assistance and support may be provided

- Vendor-side engineers can be consulted by phone or email.

- Advice and consulting on all aspects of warehouse management is available.

- Detailed manuals and consultation services are available for each use case.

It is recommended that you inquire about the nature and extent of support when requesting information or a demo.

Check company case studies and choose a good match.

Check out the case studies of vendors that provide WMS.

If your warehouse is performing industry- or industry-specific operations, the functions in a general WMS may not be able to handle your needs. In such cases, it is important to choose a product that is specialized for the specific industry or has a proven track record of implementation in the same industry.

If you choose a WMS that has a proven track record of implementation in many of the same industries as your company, your business and the system will be well matched, and you will have a better chance of achieving the desired results and resolving issues.

10 latest version WMS recommended products

The following is a list of the 10 most recent WMS recommended products, in order.

We have selected recommended products for cloud, on-premise, and package types, so please refer to them when selecting a WMS for your company.

ci.Himalayas/R2" by C-Net Corporation

This cloud-based WMS comes standard with more than 210 functions required for warehouse management, from receiving and shipping to inventory, stocktaking, and billing. Even if multiple sites are operated, related data can be centrally managed at the head office, and real-time and accurate data can be grasped, allowing the head office to issue appropriate on-site instructions.

With the No.1 share of cloud WMS sales for 11 consecutive years from FY2011 to FY2021, this WMS has been adopted by many warehouse locations and companies. It can also be integrated with external systems related to sales management and ordering, as well as other higher- and lower-level systems and material handling systems (systems that manage material handling) such as DAS, GAS, and DPS. 30-day free trial use is also available.

Official website: https://www.cross-docking.com/service/wms-standard/

Cloud Thomas" by Sekitetsu Co.

It is a cloud-based WMS with a proven track record of improving the logistics of more than 1,000 companies and is used for logistics management in a variety of industries, including BtoB and BtoC, face-to-face and online, materials, food, cosmetics, apparel, general merchandise, cosmetics, furniture, and home appliances.

A wide variety of functions have been introduced to facilitate early introduction and establishment, including an app version of the management system that allows work and operation with a smartphone, operation with a SIM card that requires no Wi-Fi installation, and CSV linkage and API linkage that allows delivery of inbound/outbound, product master information, and shipment completion information. In addition to Cloud Thomas for small and medium-sized companies, “Cloud Thomas Pro” has been released for large-scale logistics warehouses and large companies, so you can choose the type that best suits your scale and number of locations.

Official website: https://xn--gckr5a9ce1k1c3h.jp/

Logizard Corporation "Logizard ZERO

It is a cloud-based WMS that specializes in wholesale and other BtoB logistics, especially EC logistics management.

It has been adopted at more than 1,600 logistics sites and is used for a wide range of logistics management regardless of products, such as hobby, apparel, and cosmetics. We boast over 20 years of know-how and the top share in the industry for cloud-based WMS, and we also provide implementation support and support for nationwide visits.

Approximately 70% of the users who have adopted the system have implemented it without any customization, and it can be in actual operation in as little as one month. We also take advantage of the benefits of cloud computing to regularly update versions of our systems, and we are increasing the number of systems that can be linked via API/automatic integration, and we are actively promoting standard integration with external products such as material handling and logistics robots that are practically necessary or will be necessary in the future.

Official website: https://www.logizard-zero.com/

Mitani Computer Corporation "W-KEEPER

This cloud-based WMS is currently in operation at over 3,500 shippers (as of September 2023). It is highly flexible and can be used in a variety of scenarios, such as inventory management for multiple shippers, in-house centers, and outsourced logistics operations.

More than 120 diverse functions are available, including transfer between locations, expiration date and lot management, ledger correction, set and processed goods management, location management, traceability, and work progress management. You can select and add functions according to your business, industry, products handled, and issues you want to improve in your warehouse, so even though it is a cloud-based WMS, you can select and install functions that match your warehouse and logistics operations.

Official website: https://www.mtn.co.jp/index.html

Air Logi" by Commerce Robotics, Inc.

It is a cloud-based WMS with a proven track record of being implemented by more than 100 3PL warehouses and 1,200 EC businesses.

The system can be linked to a wide range of systems and allows flexible data input/output settings, making it suitable for introducing a WMS to shorten the lead time when introducing new projects. The system is also equipped with a variety of functions to prevent errors and reduce the burden of clerical work, such as batch, invoice-integrated forms, post-payment-integrated forms, and an invoice postponement unit.

The “PICKMAN” inspection application, which includes cash register inspection, voice picking inspection, instructions for forms such as delivery slips, invoices, and postpaid payment slips, and product inspection functions, can be used, making it possible to introduce handy inspection to achieve “zero wrong shipments”. It can be linked to various malls and cart systems, as well as home delivery systems and deferred payment systems, making it a strong feature for e-commerce businesses.

Official website: https://www.ec-zaiko.net/? _fsi=2cJW3JMk

Connected Linc" by Connected Inc.

This WMS is available in cloud, packaged, or on-premise models, allowing you to choose the type of WMS that best suits the points you want to focus on and the objectives you want to solve.

The non-customized cloud type can be operational in as little as two weeks, while the packaged or on-premise type can be selected if you are concerned about storing information on an external server. We can also provide server procurement and other services as needed.

Linkage to systems such as the backbone, order management, and production management is possible, and since the linkage format is based on CS linkage that has been mastered, no customization is required. Since a physical receipt can be issued at the time of receipt, WMS-based management can be realized even for products without barcodes.

Official website: https://www.cnd-g.co.jp/lp/

SLIMS, Seino Information Service Inc.

This WMS can be deployed in either the cloud or on-premise model, and has a proven track record with 400 companies and a monthly utilization rate of 99.9% for the cloud model by leveraging its strength in consulting for 3PL business and logistics improvement.

It has been adopted by many companies in the warehousing, wholesale, and retail industries, and is also in operation as a WMS for Seino Unyu’s nationwide distribution centers. It also includes functions that are practically indispensable for warehouse management in various industries, such as “part number + color and size management,” which is necessary for companies that handle apparel products.

Official website: https://www.siscloud.jp/logistics-it-cloud/solution/slims/

ZIZAIA" by Infosense, Inc.

This is a package-type WMS that can be built like an on-premise type. The low customizability of the conventional package type has been revamped, and functions can be added and removed as needed.

Efficient operations can be realized without wasting money on functions that are not used. The fee structure is based on an “enterprise license system” that does not charge for adding or deleting functions, making it suitable for building a system suitable for your warehouse operations while keeping costs low.

In addition to standard compatibility with handheld terminals from major manufacturers, the system is also compatible with tablet terminals and mobile PCs. It is also linked as standard to voice terminals (Vocollect Voice®). Voice instructions streamed from the headset and voice responses enable hands-free operation, leading to increased work efficiency.

Official website: https://www.info-sense.co.jp/zizaia/

Logi-Gres Corporation "Tanayomi".

This WMS employs “standardized customization” that allows other users to use new features that the user wishes to add.

We offer a variety of support and assistance associated with WMS, including a monthly rental service of a handy terminal, an on-site initial setup service that proposes the optimal initial setup after an on-site visit, and remote maintenance support that enables remote support from a remote location. Remote maintenance support enables remote support from remote locations.

WMS also offers a contracting service that allows you to outsource your entire warehouse-related operations, from shipping and receiving to general warehouse management, with ongoing support during the use of the WMS, making it suitable for companies that are concerned about DX and digitalization of their warehouse operations and logistics.

Official website: https://tanayomi.jp/

iWacks" by Hokko Information Service Co.

Package type WMS. It uses a shipment inspection system with QR code matching that can prevent incorrect shipments and product selection errors. By having suppliers attach QR codes, traceability from upstream to downstream of logistics can be ensured. Since the system supports multiple locations and multiple shippers, multi-location inventory can be integrated and managed on a single system.

Our proprietary package enables us to implement the system at low cost and with short delivery time. The flexibility of the system design also makes it possible to build a system that takes into account future additions of functions and the start of new businesses.

Official website: http://www.hokkohj.co.jp/service/case/index.html

Improving efficiency of warehouse operations to be addressed along with WMS implementation

By selecting and implementing a WMS that fits the number of products handled, the number of warehouse locations, and the business of the company, it is possible to resolve issues that arise in warehouse management and logistics operations. However, some companies may have issues that cannot be solved by a WMS alone, or they may be aiming to improve the efficiency of their overall operations.

If you are looking to streamline and optimize your warehouse operations, please contact Taiyo Kogyo Corporation. For example, our tent warehouses are suitable when you want to easily add a base of operations to improve work efficiency. We have experience in introducing this system to a wide range of companies, so please feel free to contact us for more information.

Click here for a list of Taiyo Kogyo Corporation’s products and services, or click here to request information materials.

https://www.tentsouko.com/

Choose a WMS that matches your business and the issues you want to solve.

Tent Warehouseへの

Any Inquries

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- MakMax Plus>

- Explains the advantages of WMS (Warehouse Management System) and how to choose one! In-depth comparison of the latest 10 WMS products, including the company with the No. 1 market share