Details of Research and Development

We are committed to technological development and research in order to solve the problems of our customers and society.

Research and Development

The technical research laboratories and the development departments of each business take customer needs and social issues as their starting point,

We are engaged in technological development mainly in the fields of "construction," "civil engineering," "logistics," "energy," and "environment.

- Architectural Business

- Public works

- Logistics

- Energy

- Environment

Material Development

In order to deliver highly functional membrane materials that meet customer needs, we conduct in-house material development and create new value for membranes.

Materials and products developed by our company

Material Evaluation

In order to provide materials with confidence to our customers, we use a variety of evaluation techniques to determine the reliability of materials.

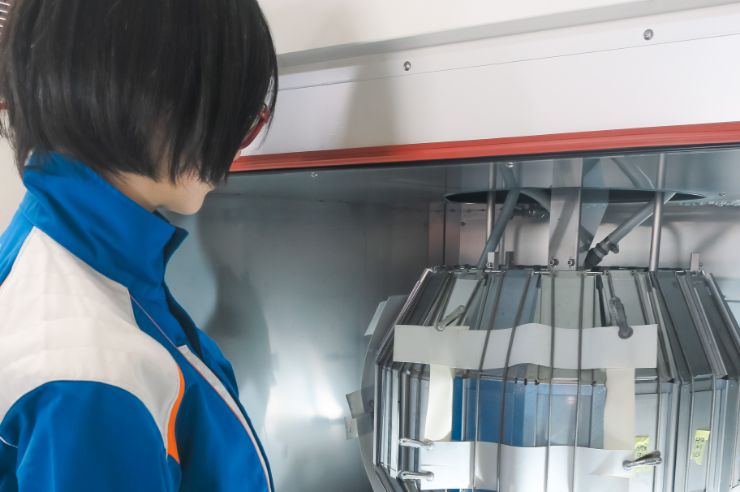

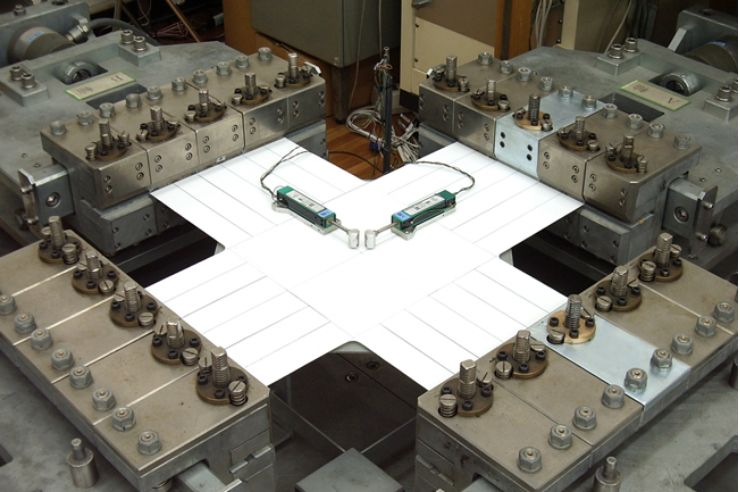

Contract testing and experimentation

Our contract testing began in 1970 at the Osaka Expo.

We accurately and quickly inspect and test the durability, safety, and quality of materials used in membrane structural buildings and membrane materials. Testing is performed at the world's first ISO/IEC 17025:2005 certified membrane structural testing laboratory, Technical Research Institute (Osaka, Japan), which is ISO/IEC 17025: 2005 certified, ensuring the reliability of measurements and test results in testing tensile membrane materials and structures.

ISO Certification

biaxial tension test

New Technology Development

We are constantly developing new technologies to ensure the comfort of all users of membrane buildings and our products.

Bridge exterior materials wrapped with membrane, bridge wrapping

The membrane surface of the bridge wrapping serves as a permanent scaffold for the bridge. Compared to conventional inspection scaffolds made of metal panels, the interior of inspection scaffolds is brighter, allowing inspection work to proceed more efficiently.

The area under the guard, which has a dim and dreary image, is transformed into a space with a clear and pleasant atmosphere by wrapping the huge structure with the membrane material. The membrane material, which is resistant to stains and retains its whiteness, has a high light reflectance (visible light reflectance of approximately 77%), brightening the entire space under the girders. (NETIS:KK-130051-A Membrane-type bridge exterior construction method)

Lightweight and soft, a new concept in safe ceilings

Membrane ceilings create beautiful and comfortable spaces in addition to being light, soft, and strong for safety and security. Ceilings are not only at risk of falling during major earthquakes. Ceilings falling due to aging and deteriorating base materials, daily delicate vibrations, wind and thermal contraction, and other such causes have been reported all over the world today. Instead of heavy and hard conventional ceilings, a new concept of soft, lightweight and strong membrane ceilings gently wrap people's lives.

ECTFE membrane material realizes "1% degree of fogginess" for fall prevention fences

The transparent membrane material of ECTFE (Ethylene-Chlorotrifluoroethylene copolymer) is used to prevent riders from falling and jumping water when installed at highway curves. This is a fall prevention fence with a membrane structure that has high impact resistance and excellent landscaping properties, using ECTFE membrane material with a "blur rate of 1%".

Recycle TAICON after it has served its purpose.

We are working on recycling container bags (tycons) into molded plastic products. EVA tarpaulin tycons, which were previously disposed of or incinerated after 15 years of useful life, are now being recycled into tycons again, rather than being processed into recycled products.

About Research and Development

- TOP>

- Research and Development>

- Details of Research and Development