MakMax Plus

Durable years of warehouses│Standards for useful life and ways to extend durability as specified by the IRS

2019.09.02

Durability is a concern for tent warehouses.

The estimated durability over time is about 10 years, but it can be longer or shorter depending on various factors such as the use of the tent warehouse, materials, and location.

It is often affected by sudden natural disasters, not to mention the need for frequent checks and maintenance.

In this issue.

- How the useful life of a tent warehouse is determined

- How can signals of deterioration be found in daily use?

- Is there a way to extend the durability?

I would like to explain about the following.

How is the service life of a tent warehouse determined?

For a general idea of the useful life of a tent warehouse, the IRS’s Standard Schedule of Useful Life of Depreciable Assets is helpful.

Tent warehouses are listed as “metal construction > for factories and warehouses (general use)” and are listed as “31 years” here.

> [Reference] National Tax Agency, “Useful life of depreciable assets (buildings/facilities)

However, this is only a general standard value from a depreciation perspective and does not indicate the actual durable years.

It is mainly “location and weather conditions” and “materials” that determine the actual durability of a tent warehouse.

location (e.g. of industry)

For example, the tent fabric (membrane material) that makes up a tent warehouse gradually deteriorates due to ultraviolet rays.

Sunlight hours play a major role, and the longer the membrane material is exposed to ultraviolet rays, the faster it deteriorates. In sunny and sun-drenched locations, the durability of tent warehouses tends to be relatively short.

Membrane materials and steel frames are also affected by sea breezes.

In coastal areas where sea winds blow, the membrane material will also deteriorate and the durability period will shorten.

Furthermore, the degree of impact on materials depends on the quality of the ground.

Since the optimum solution for tent warehouse specifications and materials varies depending on the location, consulting with a specialized business can be expected to extend the durability period of the site.

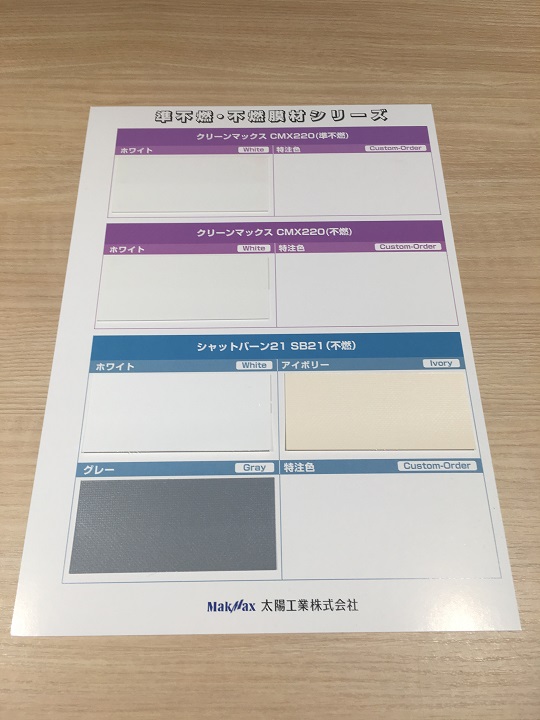

(raw) material

A typical tent warehouse is mainly composed of a steel frame and a tent fabric (membrane material).

The steel frame is considered to be approximately 30 to 40 years old, and the tenting (membrane material) is considered to be approximately 10 to 15 years old when it should be replaced or repaired.

In recent years, however, advances in research and development have led to the development of new materials for steel frames and membrane materials used in frames, making it possible to achieve longer durability.

酸化チタンの準不燃膜材と不燃膜材。条件によっては耐久年数は20年

Since durability is an important factor directly related to cost, when considering tent warehouses, tent warehouse manufacturers and operators with the latest technology and knowledge should be consulted to recommend the best materials.

Checks and maintenance extend durability.

Durability, which varies by location and materials, cannot be maximized without proper maintenance.

Early detection of signs of deterioration in tent warehouses and frequent implementation of necessary maintenance will, above all, extend the durability of these facilities.

Next, here are some items to check for condition in order to find signs of deterioration in tent warehouses.

Related Documents: Download a 5-minute comparison of warehouse construction

Tent warehouse condition check items

There are three main categories of items to check to determine the condition of a tent warehouse : framework, tents, and sliding doors.

Failure to check the warehouse could result in damage to items placed inside the warehouse due to leaks from the ceiling or deterioration of the tent ground (membrane material). There is also a non-zero chance of a tent warehouse suddenly collapsing if frame damage goes unnoticed. It is important to know what items should be checked regularly.

1. framework

The framework should be routinely checked for bent or deformed areas. Joints and foot bolts and braces should be inspected regularly for looseness.

2. Tent

Be on the lookout for any frayed or torn areas or holes in the tent. Damaged areas can lead to leaks and insect and rodent infestation. It is also a good idea to check the belts and ropes that secure the tent to the steel frame for damage.

擦り切れや破れを補修した写真

3. sliding door

Finally, sliding doors, which are the entrances and exits to tent warehouses, should be looked at for heavy opening and closing action, distortion or dislocation of the doors or rails, or loose mounting screws. And if any of these deteriorations are found, it is important to promptly contact the manufacturer’s representative for action.

DSC_0798

扉破損の修理前(上)と修理後(下)

How to Extend the Durability of Tent Warehouses

The only way to extend the durability of a tent warehouse is through regular maintenance and repair. It is advisable to maintain tent warehouses from the early stages of deterioration, as well as when abnormalities are discovered during condition checks.

The replacement of the tent is especially important. If the tent membrane deteriorates, rainwater entering through it can damage the steel frame that serves as the frame, which can end up being more expensive.

雨水でフレームの鉄骨が腐食

For steel frame rust and corrosion, it may be necessary to clean (polish the surface), repaint, or weld the steel frame. Not only is this costly and time-consuming repair work, but the corroded steel frame may in turn damage the tent membrane. There is no possibility of the entire tent warehouse falling into a vicious cycle of deterioration.

So how often should regular maintenance be performed to extend the durability of a tent warehouse? This depends on the membrane material used.

Extending durability requires expert knowledge

Because it is not easy to accurately assess the condition of a tent warehouse and perform appropriate maintenance, it is common practice to hire a specialized business to do this for you.

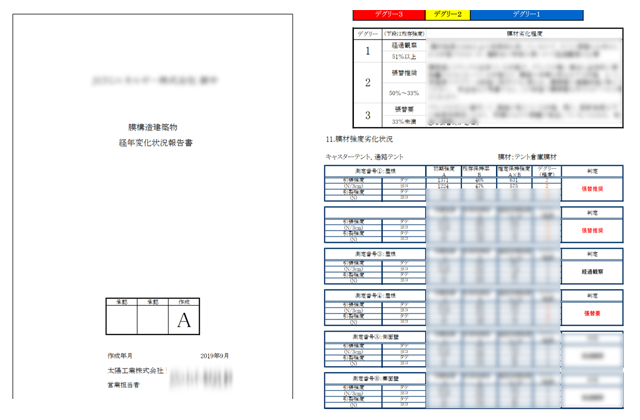

Taiyo Kogyo Corporation, a tent professional that has been in business for about 100 years, offers ” Membrane Material Deterioration Diagnosis, Repair and Repair Service ” to deal with aging and deterioration of tent warehouses.

TACS (Taiyo After Care Service), a diagnostic service for rebuilding, replacement, and deterioration of membrane materials, is also used to rigorously check the deteriorated condition of tent warehouses.

We basically conduct surveys free of charge (with some exceptions), so please feel free to consult with us.

建替・張替・膜材劣化診断の報告書

Related Documents: Download a 5-minute comparison of warehouse construction

Taiyo Kogyo headquarters also uses tent warehouse technology

Taiyo Kogyo’s headquarters is also built using tent warehouse technology.

The “MakMax Flex Experience Center” is not a tent warehouse, but an office with a membrane structure (tent structure). The “MakMax Flex Experience Center” is not a tented warehouse, but a membrane office building, but it is rich in tent construction know-how.

It is also a hands-on facility built based on the concept of “a facility where customers and employees can gather, meet, and experience together,” so why not come and experience the technology for yourself?

膜構造(テント構造)による事務所。見学受付中です

Learn more about our tent warehouses and services .

Tent Warehouseへの

Any Inquries

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- MakMax Plus>

- Durable years of warehouses│Standards for useful life and ways to extend durability as specified by the IRS