Taiyo Kogyo Column

[EXPO 2025 Osaka, Kansai] EXPO × TAIYO: Where World-Class Membrane Architecture and Event Operations Come Together

2025.06.26

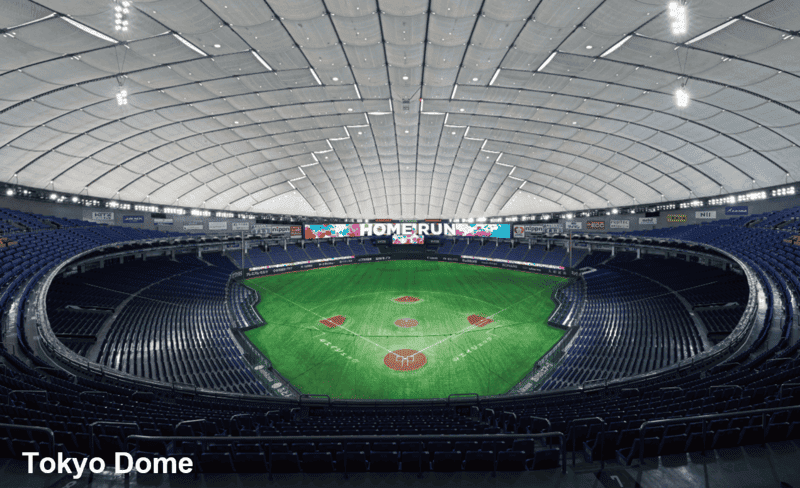

In 1970, the Japan World Exposition was held in Osaka—the first international exposition in Japan and also the first in Asia. At this historic event, Taiyo Kogyo, a leading company in membrane structures, was responsible for approximately 90% of all membrane architecture at the Expo. Notably, the “air dome technology” used in the U.S. Pavilion later inspired the construction of the Tokyo Dome.

Fifty-five years later, our experience in designing membrane structures for world expos, large stadiums, and international airports has evolved further. At EXPO 2025 Osaka, Kansai, we are proud to contribute to numerous groundbreaking pavilions in collaboration with major architectural firms and pavilion organizers.

In addition, our group companies, TSP Taiyo and ACTIO, are also involved in pavilion operations, providing comprehensive support from construction to management.

In this article, we introduce some of the pavilions at EXPO 2025 Osaka, Kansai in which the Taiyo Group is involved in.

Bring together the Taiyo Group’s solutions

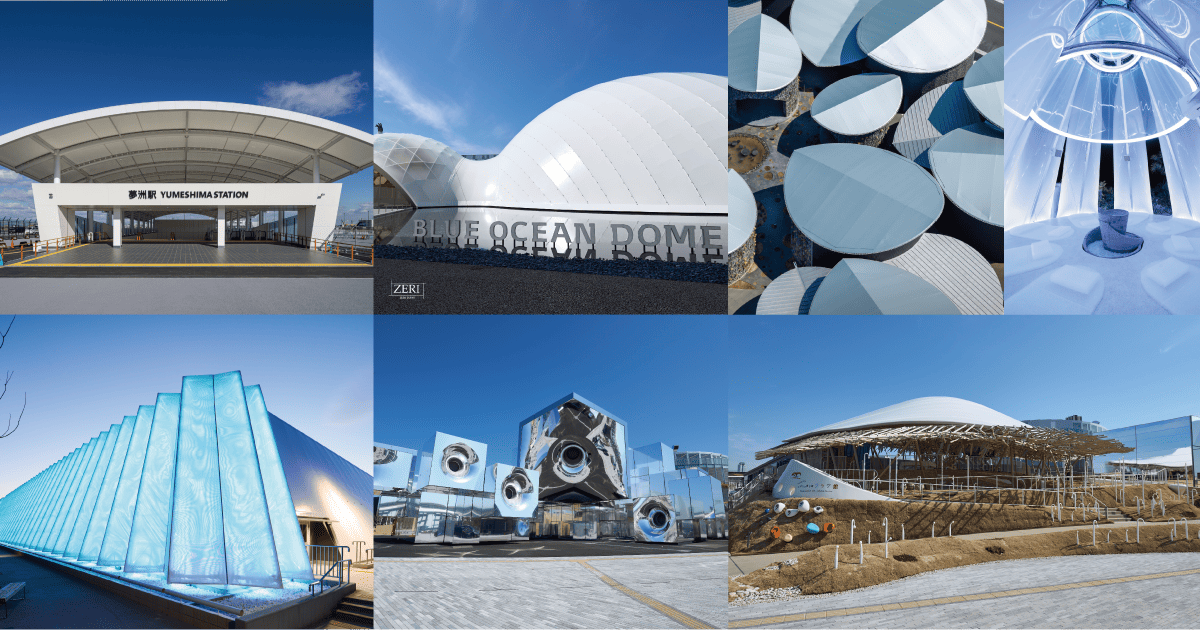

EXPO SAUNA TAIYO TSUBOMI

Silver Partner

Designing, manufacturing, and installing the ETFE film structure

Designing and construction of the whole pavilion

Management

This facility embodies a more flexible and brighter future society that the Taiyo Group, which is involved in all processes from designing, construction, and installation to management, wishes to build.

Taiyo Kogyo Corporation designed and installed the ETFE film structure, which is tailored to the shape of the sauna and allows natural light to pass through, while TSP Taiyo was in charge of the construction of the whole pavilion. ACTIO is in charge of the management of the facility so that approximately 15,000 people can enjoy the sauna during the Expo.

A membrane roof that provides a bright, open space for visitors

Yumeshima Station

Designing, manufacturing, and installing the station’s membrane roof

Yumeshima Station, a new station extended from Cosmosquare Station, opened on January 19, 2025, serving as the gateway to Expo 2025 Osaka Kansai, which started on April 13.

The membrane roof, which was adopted due to its safety, lightness, and high durability, is made of PTFE membrane material. The titanium dioxide photocatalyst used in the surface treatment breaks down organic dirt and allows the dirt to be washed away with rainwater, resulting in a high level of stain resistance that maintains the roof’s white appearance for a long time.

A mesh membrane that effectively controls water movement

Future of Life (Producer: Hiroshi Ishiguro)

Designing, manufacturing, and installing the mesh membrane for the facade

The theme of the signature pavilion “Future of Life,” created by Thematic Project Producer Hiroshi Ishiguro, is “Amplification of Lives.”

Focusing a spotlight on water, a symbol of life, the facade features water flowing along the unevenness of the black mesh membrane on the wall, giving the appearance of waves.

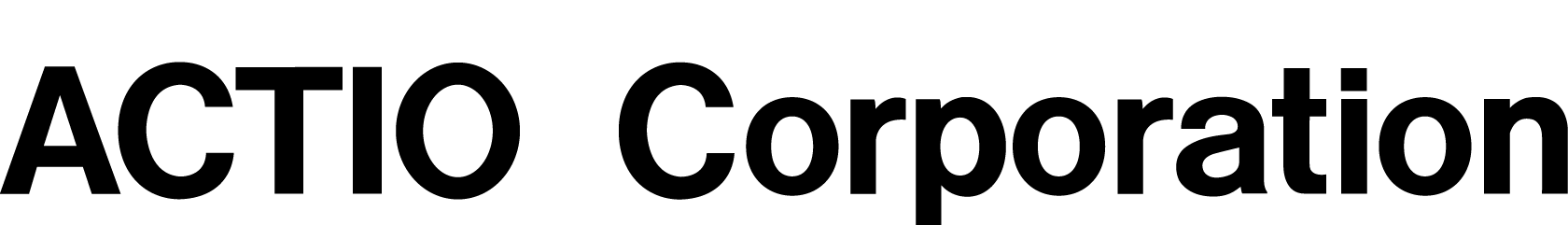

A soft, voluminous membrane roof that embodies the fluctuations of lives

Playground of Life: Jellyfish Pavilion (Producer: Sachiko Nakajima)

Designing, manufacturing, and installing the Taiyo Truss Roof (TTR) that combines TM trusses and membrane materials

The theme of the signature pavilion “Playground of Life: Jellyfish Pavilion,” created by Thematic Project Producer Sachiko Nakajima, is “Invigorating Lives.”

The roof of the pavilion features random trusses supporting a soft, voluminous membrane roof that embodies the fluctuations of the lives of all people and all things.

The pavilion creates a space where people can meet and enjoy “fluctuating play,” regardless of differences such as nationality, age, gender, or whether or not they have a disability.

Providing a new experience with a mirror membrane that distorts the reflected scenery .

null2 (Producer: Yoichi Ochiai)

Designing, manufacturing, and installing the facade using a mirror membrane and its mounting hardware

The theme of the signature pavilion “null2,” created by Thematic Project Producer Yoichi Ochiai, is “Forging Lives.”

The facade of the pavilion features a mirror membrane and a box-shaped aluminum frame. The extended mirror membrane reflects the surrounding scenery like a mirror, and the view changes dramatically depending on the viewing angle.

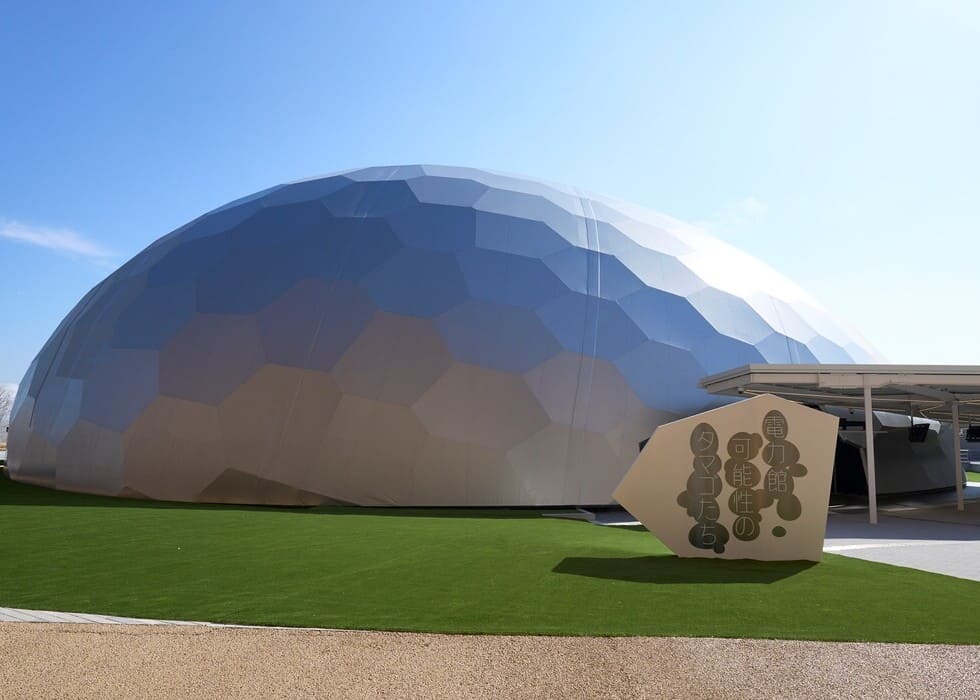

A suspension membrane structure that helps achieve the highly challenging surface shape

Dynamic Equilibrium of Life (Producer: Shin-Ichi Fukuoka)

Designing, manufacturing, and installing the membrane roof and cables

The theme of the signature pavilion “Dynamic Equilibrium of Life,” created by Thematic Project Producer Shin-Ichi Fukuoka, is “Quest of Life.”

The organic form that expresses life has been achieved by using a suspension membrane structure that stretches the membrane over cables. The design concept is “Ever-changing Architecture.”

The sphere, called the Sun for the Next Generation, symbolizes the rising sun and a future brought about by clean energy. Netherlands Pavilion

Designing, manufacturing, and installing TM trusses

The Netherlands aims to work with people to create healthy and happy societies, with the participation theme being “Common Ground”—common sharing and new value creation.

The internal steel frame of the sphere at the center of the building, which symbolizes the rising sun and clean energy, is constructed using TM trusses.

Solid technological prowess that enabled the Pavilion to be the first official participants’ pavilion to be completed, conveying tradition and culture

Ireland Pavilion

Design procedures and construction of the entire pavilion

The Ireland Pavilion’s theme is “Creativity Connects People.” Based on an architectural design by the Irish government, TSP Taiyo was involved in handling design procedures and the construction of the entire pavilion.

The three spiral pattern, based on the traditional Irish symbol the “triskele,” represents Ireland as a nation, its relationship with Japan, and the spirit of creative collaboration. The exterior walls are made of Irish-grown timber.

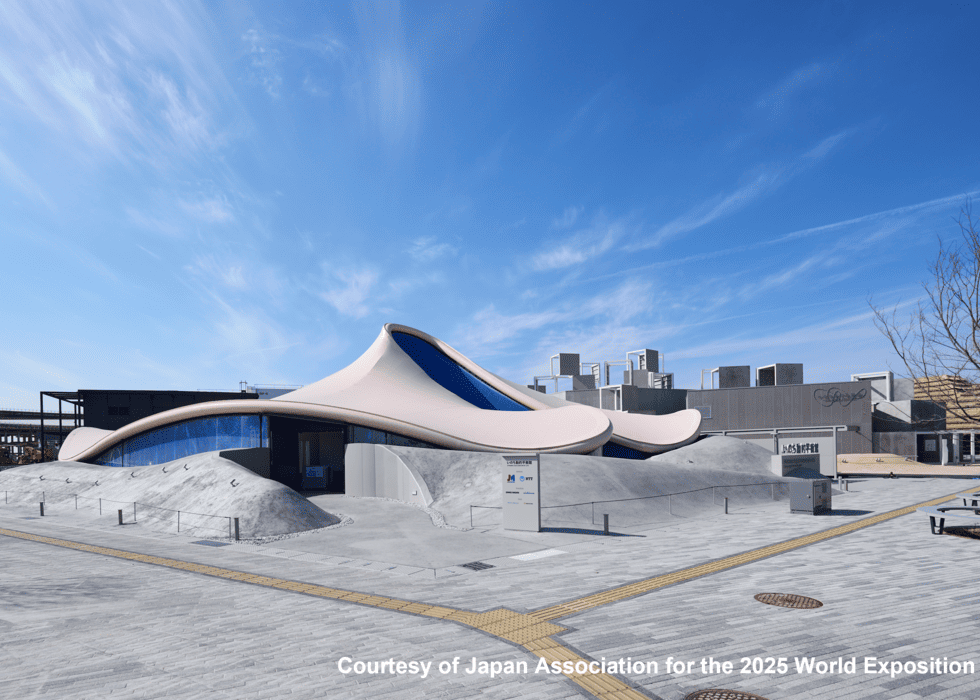

A membrane that changes appearance, expressing many possibilities

Electric Power Pavilion—Eggs of Possibilities

Designing, manufacturing, and installing the membrane

Recruitment, selection, and training of staff; venue management

Looking beyond carbon neutrality, the Electric Power Pavilion showcases the future of society from the unique perspective of the electric power industry supporting the foundation of society.

The exterior uses a Voronoi structure that combines various planes, and its surface is covered with a silver membrane.

Changing its appearance depending on the weather and time of day by capturing light from various angles, it symbolizes many possibilities for the future and harmonizes with nature and the surrounding environment.

Visitors can experience energy technology that will pave the way to the future through a variety of experiences, such as moving, touching things, and being surrounded by sound and light with an egg-shaped device, which is a one-of-a-kind item in the world.

Installation in limited space and the challenge of installing a large single membrane

BLUE OCEAN DOME

Designing, manufacturing, and installing the membrane

Management

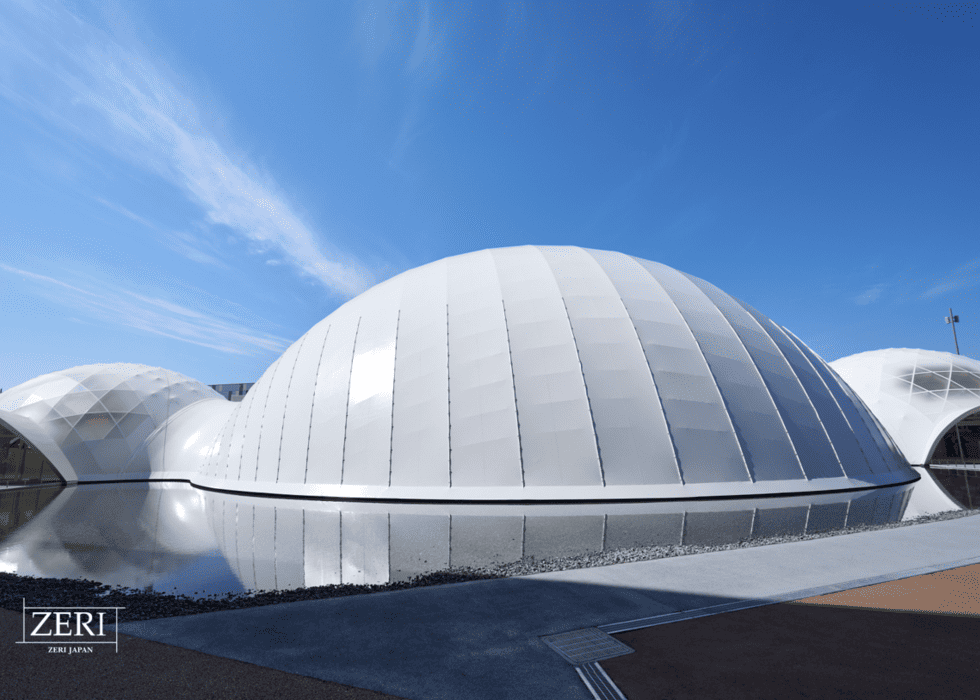

BLUE OCEAN DOME is a pavilion where visitors can learn about the concept of environmental protection while having fun, based on the theme of sustainable use of marine resources and protection of marine ecosystems.

The pavilion consists of three domes according to the themes of circulation, ocean, and wisdom.

One of the highlights is a giant spherical screen measuring 10 meters in diameter, which displays three-dimensional images that reveal the reality of marine life and marine pollution.

The roof of the ocean dome uses a single piece of transparent, non-flammable membrane material.

A membrane material that creates a temperature difference between the inside and outside, embodying the concept

GAS PAVILION OBAKE WONDERLAND

Designing, manufacturing, and installing the membrane roof and steel frame

Obake Wonderland is a pavilion that focuses on decarbonization under the concept of “Bakero–Shape Our Future!” The pavilion plans to showcase the gas industry’s efforts towards the goal of achieving carbon neutrality by 2050.

The silver membrane that covers the entire pavilion is made of a radiative cooling material developed by SPACECOOL, which changes the temperature inside and outside by about six degrees.

Reaching a maximum height of approximately 18 meters, the pavilion is characterized by its complex shape and the highly reflective material.

Fusion of Nishijin brocade techniques and the technology of processing, designing, and installing a membrane structure

Joint Pavilion Iida Group × Osaka Metropolitan Univ.

Development of a Nishijin brocade membrane and designing, manufacturing, and installing the membrane and steel frame

It is the world’s first building clad in Nishijin brocade fabric. In addition to the developed membrane material, the pavilion features pattern matching and a complex shaped steel frame.

The concept of the exterior design is “Sustainable Mobius.”

The design expresses people’s unchanging desire to live happily and their hope for a radiant life.

The fusion of the future and tradition is made tangible by covering the entire surface with specially processed Nishijin brocade fabric.

Construction of a pillar-free space, providing a seamless experience for guests to make Osaka’s food culture known to the world!

ORA Gaishoku Pavilion 『~UTAGE~』

Designing and constructing the exterior structure excluding the facade

As a prime contractor, TSP Taiyo was in charge of designing and constructing the exterior structure, excluding the facade.

The aim of this pavilion is to establish 『~UTAGE~』 in the world as a new way of dining out, and also to deliver the five actions of hospitality, food tasting experience, new frontiers, liveliness, and development of the food service industry.

A 150-meter-long self-cleaning white membrane

Future City

Order taken for the complete construction work including designing, manufacturing, and processing the trusses, membrane roof, and membrane facade

A future society where Society 5.0 is realized has been created in both physical and virtual spaces through diverse co-creation. At this pavilion, visitors can virtually experience a future city, food, culture, and healthcare, which will be made possible by a variety of innovations, and also actions toward the future.

Taiyo Kogyo Corporation received an order as the prime contractor for the complete construction work, including the work related to the building’s membrane roof and exterior facade.

The building features a “double-skin” facade made of two layers of titanium dioxide photocatalyst polyvinyl chloride (PVC) mesh membrane developed by Taiyo Kogyo Corporation. This mesh membrane has a self-cleaning function that absorbs sunlight to break down surface dirt and then washes the dirt away with rainwater.

It is white during the day and changes into various colors at night when lit up.

Leaf-like membrane roofs that connect various spaces

Future Life Village (Exhibition facility)

Designing, manufacturing, and processing the membrane roofs

The courtyard, which is inspired by the wetlands of Yumeshima Island, is lined with units where various exhibitions and events are held. Visitors can freely walk around the exhibits through a ring-shaped corridor that connects the units. Light and wind flow through the verdant walls of the courtyard and rainwater is circulated for reuse. The landscape and architecture are closely connected as an attempt to create an environmental space of the future.

A series of semi-outdoor spaces with leaf-like roofs are scattered throughout the building, creating a variety of places that are loosely organized like a pleasant forest.

Pursuing a sense of openness and a beautiful shape created by membrane

Pop-Up Stage Inner East

Designing, manufacturing, and installing the membrane roof and cable equipment

A Pop-Up Stage is an outdoor event space of approximately 50 m2 with no seats available. There are five Pop-Up Stages in the Expo site, all of which face a walkway. These Stages are suitable for live music and other performances as well as small-scale stage events.

Taiyo Kogyo Corporation considered the details while keeping an eye on costs and meeting the requests of the architectural design office.

Please pay attention to the transparency of the membrane and its hanging shape.

A sunshade tent that provides a comfortable space

Wind Plaza (Sunshade Tent)

Bronze Partner

Foundation, steel-frame, and membrane work

The Taiyo Group is sponsoring the facility as a Bronze Partner.

The logos of the three Group companies are displayed on the tent. TSP Taiyo was responsible for the foundation, steel-frame and membrane work.

A bright open space

TSUKIGESYO x UNAGIPIE Osaka Expo Store

Designing, manufacturing, and processing the membrane roofs

The Futuristic Challenge Shop is open to a wide variety of participating companies and organizations, regardless of their size or industry. As part of the Future Society Showcase Project, it aims to offer visitors hands-on experiences with new technologies, social systems, and lifestyles related to food, retail, and services.

To ensure visitors can comfortably enjoy these new lifestyle experiences, the shop features a simple gable-shaped membrane roof, creating an open, bright, and airy space of approximately 250 square meters.

A leading company pursuing the infinite possibilities of membranes

Taiyo Kogyo Corporation’s representative solutions

Breaking through what

membranes can do or be

Architectural Business

Taiyo Kogyo Corporation’s membrane structural products and technologies bring freedom and flexibility to architecture and functional and comfortable spaces to industry. We create attractive buildings that brightly illuminate life and society, and people and the earth.

Logistics Business

As a leading company in the industry, we provide “Quality x Service x Support” utilizing our extensive experience and know-how cultivated over many years.

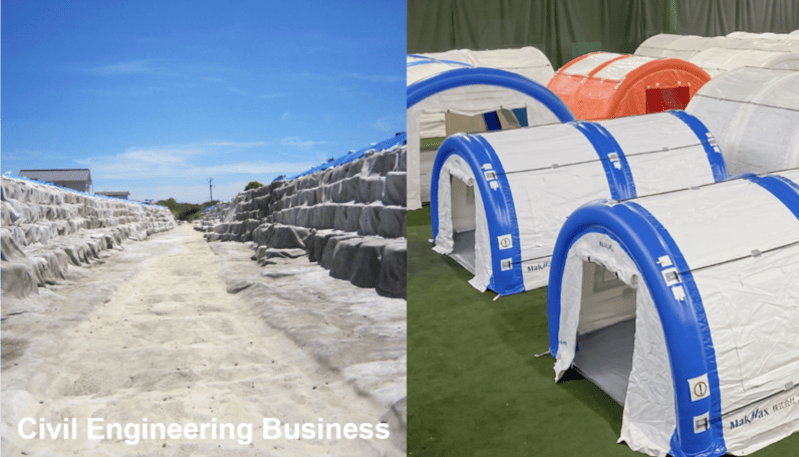

Civil Engineering Business

Utilizing the membrane technology that we have cultivated, we have created many high-quality products and construction methods that are useful for environmental protection and disaster prevention and mitigation. We are actively working to solve various issues to support safe and secure lifestyles and protect our precious environment.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- [EXPO 2025 Osaka, Kansai] EXPO × TAIYO: Where World-Class Membrane Architecture and Event Operations Come Together