MakMax Plus

Material evaluation professionals who support the quality and reliability of Taiyo Kogyo

Naomi Nakagawa

Technical Development Department Technical Research Laboratory

2024.03.13

Nakagawa majored in food and nutrition in college.

He joined the company four years ago as a temporary employee and became a full-time employee in January 2024. Although he started with no experience, he is currently leading a team as a leader and promoting material evaluation, testing, and analysis. What is the reason why he has grown to the point where his own department and other departments depend on him in an industry he first jumped into?

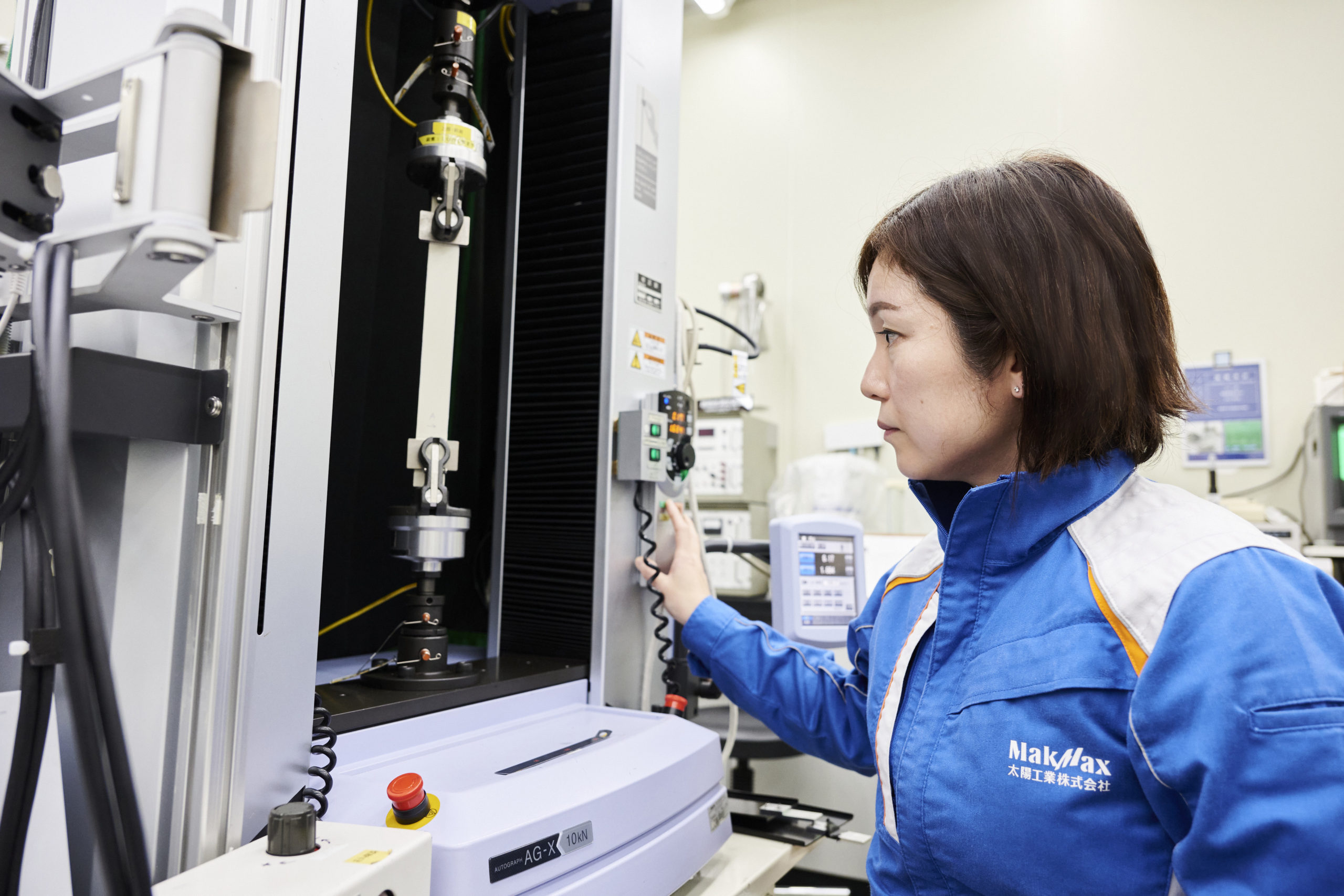

Developing new evaluation methods to meet diversifying needs and applications

The mission of “Material Evaluation, Testing and Analysis” is to conduct tests and analyses suitable for membrane materials to evaluate whether they are of a quality that can be released outside the company. We check the strength using a machine that pulls up and down, and measure the resistance using equipment that simulates processing and installation, and share the test and analysis results with the relevant personnel so that we can deliver membrane materials of reliable quality to our customers. Since we always have seven to eight projects, it is essential to manage the schedule in reverse from the delivery date. When the arrangements I have made like putting blocks together proceed as planned, I am filled with a sense of accomplishment. I am filled with a sense of accomplishment.

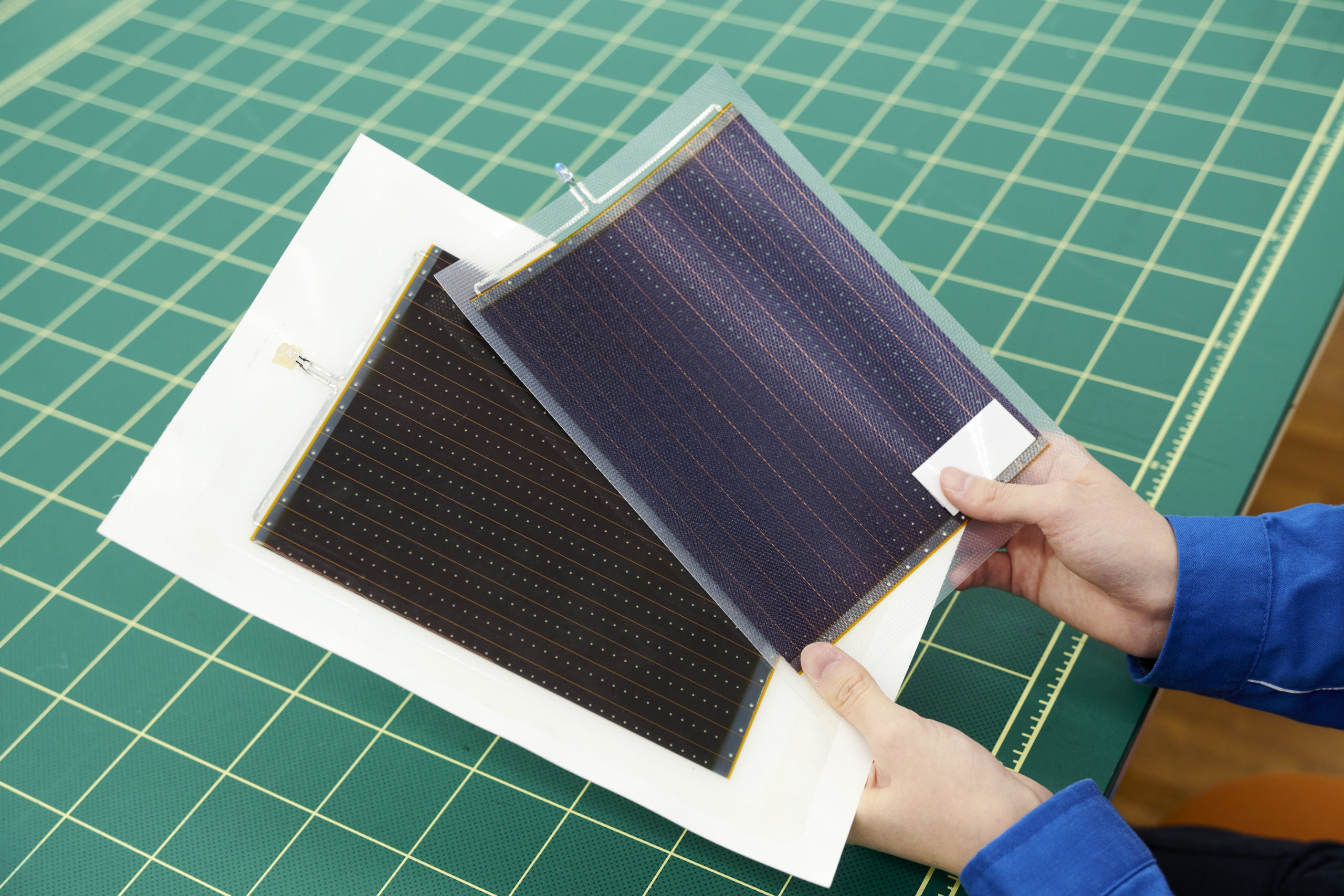

Since membrane materials have diverse functions and applications, there are many cases where evaluation methods have not been established. One example is the evaluation of adhesion. Membranes are composed of a textile and a coating material, and if the two are not adhered to each other, errors will occur over time. In order to prevent errors before they occur, the team devised a method of measuring the strength of the yarn as it is pulled from the textile.

Even when a defect is found in the field, we are required to develop an evaluation method, so all members of the team are working together with their wisdom to develop a new test.

The joy of doing a job you love, gained through overcoming failure and self-doubt

Now, as a leader, I am in charge of managing the testing process and supervising junior staff, but I cannot count the number of times I was depressed when I first joined the company, such as when I cried because of my own inadequacy or made a mistake on a sample that was only one. I chose our company because I had always liked detailed work, but when I entered the company, I found that the people around me were all professionals who knew everything about membranes. Naturally, there is a gap in the amount of knowledge, so I could not express my opinions well in discussions, and I lost my confidence more than once or twice. However, at such times, my supervisors and seniors always

What are you going to do with this test when Mr. Nakagawa is gone?”

He encouraged me to keep going. It is because of his warm support that I have been able to continue to work with him to find solutions. Above all, I love my job. I feel that “material evaluation and test analysis,” in which I work with my hands in a creative manner and the results are expressed in numerical values, is my true calling.

I have accumulated a wealth of experience at our company, including in the construction of a variety of facilities, and I myself have become involved in a wide range of facilities. I am impressed when I visit these facilities in my private time, and I feel a sense of pride that we are supporting the company’s credibility, which is the driving force behind my work.

Taiyo Kogyo's strength is its ability to implement PDCA cycles with a sense of speed.

The difficult part of this job is that we have to come up with evaluation methods from scratch for items for which there are no test standards. For example, the design department may ask, “A defect occurred during construction. What is the reason?” we can predict the cause, but we have to think about what kind of tests and analysis we need to conduct to explain the problem theoretically. This is a difficult problem that is too big for one person to handle alone. For this reason, I always ask those around me, “What do you think?” I always ask questions as if I were standing around talking. The Technical Development Department is a group of membrane professionals. If you ask someone, you are sure to get an idea. This always leads to an idea. Discussions are always going on in the laboratory. I think the appeal of our company is the openness that allows people to express their own ideas regardless of age or position.

The people with whom we discuss are not limited to those in our departments. There are many departments that request testing from us, and the requirements are different for each. Even if we simply say “strength,” the test method will vary depending on the situation, such as whether the strength is measured by pulling in a straight line or by wrapping and then pulling. That is why you must ask questions repeatedly until you are satisfied. It is no exaggeration to say that smooth communication with our own and other departments enhances our quality.

I am very happy when the results meet the expectations of the other party, and the relationship of trust that has been established has made it easier to cooperate with each other than before. I feel that Taiyo Kogyo’s strength lies in this environment where discussions are held on the spot and countermeasures are developed.

The current motivation is the Expo project. Improve your skills at in-house study sessions.

I am now very excited to be working on a project for EXPO 2025 Osaka-Kansai Expo. We are evaluating materials that have never been used before, using testing methods that have never been used before, and providing feedback on the results. It is very rewarding to think that we are evaluating these materials for their release into the world. This challenge has increased my ambition, and I now make it a point to attend the twice-weekly study sessions held at the company. I want to absorb the knowledge of the big veterans and acquire the knowledge and skills to flexibly respond to any project.

Our goal is to make evaluations so that people can say, “Taiyo Kogyo products can be used with confidence. To achieve this goal, we are now working to standardize our testing procedures. We will establish rules for techniques that have been passed down from person to person, so that the same results will be obtained no matter who conducts the tests. I would be happy if we can move forward while keeping a firm footing, and make the laboratory something that all of us at Taiyo Kogyo can be proud of in the future.

Related Articles

- TOP>

- MakMax Plus>

- Material evaluation professionals who support the quality and reliability of Taiyo Kogyo