Taiyo Kogyo Column

Recycling container bags (TAICON) into plastic moldings. Taiyo Kogyo’s innovations weave a sustainable future.

2024.03.13

In the spring of 2021, Taiyo Kogyo began a new challenge.

A General Manager proposed SDGs actions that reflect our status as “a leading company” .

Thus, the EVA tarpaulin recycling project came to life.

We talked with the leader of this project Takayuki Nakanishi (Nakanishi) and one of the members Mitsuo Toya (Toya) about this project.

Left: Mitsuo Toya

Logistics Business Headquarters Technology Department Joined in 2012

Right: Takayuki Nakanishi

Logistics Business Headquarters Development Officer Joined in 1995

"From TAICON to TAICON."

A project for SDG measures leading innovation.

The challenge now begins.

The EVA tarpaulin recycling project is undertaken by a team of selected experts.

Takayuki Nakanishi (“Nakanishi”) of the Logistics Business Management Div was selected to lead this project.

Will it be possible to restart this effort, which has not progressed for a long time?

Facing unknown challenges, Nakanishi is determined to ;ead this project,

focusing not only on our contribution to the environment, but also meeting the expectations of our customers.

Nakanishi:

Taiyo Kogyo has taken advantage of the characteristics of lightweight and strong “membranes” to expand their applications not only in the construction field, but also in the civil engineering, logistics, and environmental fields. In particular, we have established ourselves as a leading company in the industry, boasting the world’s top share in the manufacture of large membrane structures. Along the way, I have responded to the needs of many customers as a sales representative.

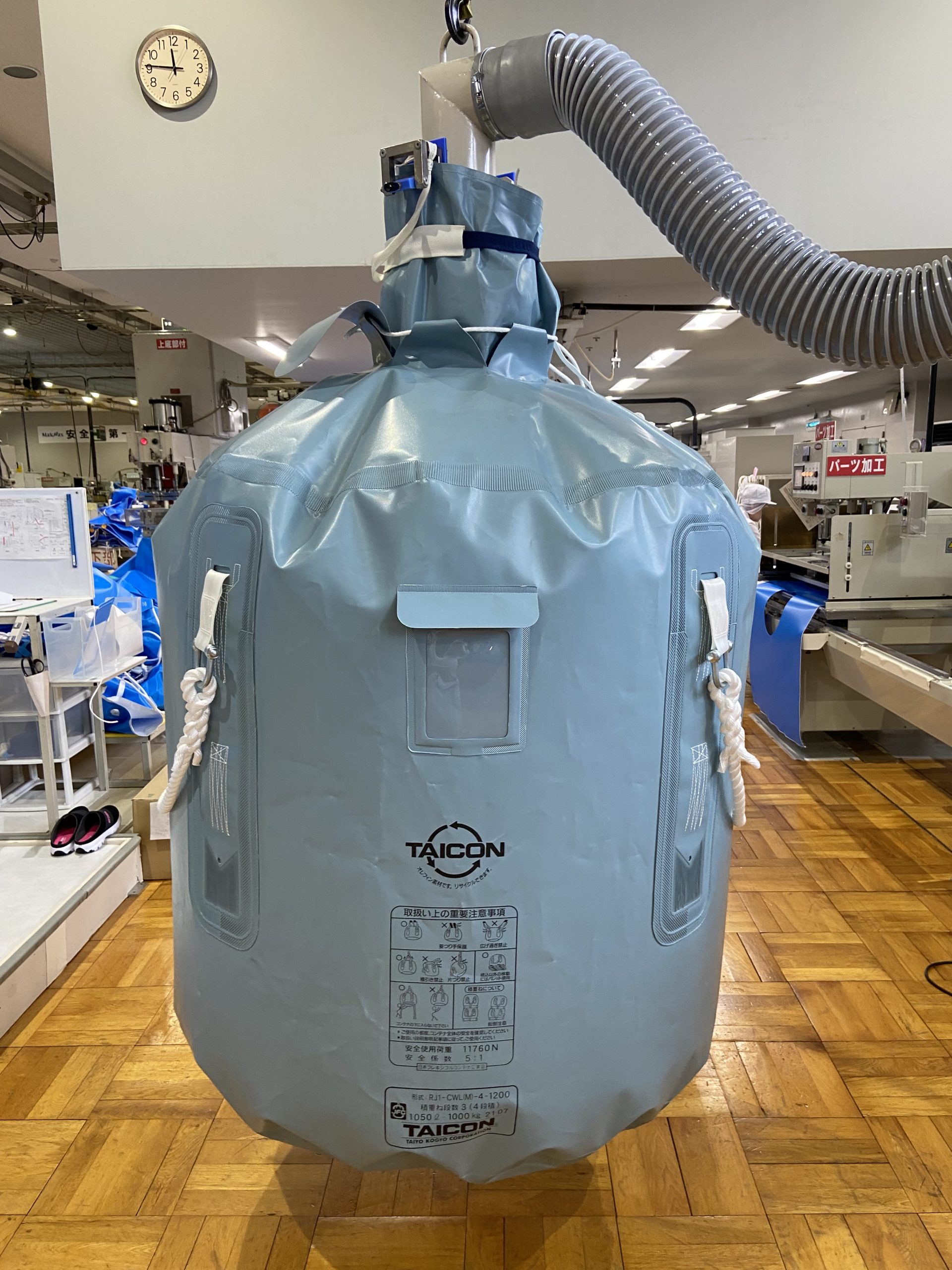

In 2020, an innovative project has begun. This is an important beginning of a new chapter for us at Taiyo Kogyo. At the heart of this project is EVA tarpaulin recycling. The aim is to recycle our flagship product, the container bag “TAICON” , which was developed to transport large quantities of powder and granular materials.

Designed to be highly functional, “TAICON” serve the roles of packaging, transportation, and storage, and can be reused. Previously, “TAICON” were disposed of or incinerated at the end of their lifecycle. This project is a challenge to create a system to recycle them. Furthermore, the project aims to achieve zero CO2 emissions through efficient chemical recycling, which is expected to contribute to the environment.

This project was the brainchild of the General Manager of the Logistics Division (“General Manager”). The General Manager came up with the idea of recycling a TAICON to TAICON, calling it “from cradle to grave, and to new life”. It was an unprecedented new perspective and flexible thinking.

In fact, I have been involved with TAICON for about 20 years as a sales person and have attemted to recycle them in the past. I was doubtful and skeptical about the value in this effort.

However, this revitalization from TAICON to TAICON was unexpectedly met with a great deal of anticipation. The expectations were particularly high from customers and management interested in ESG investment, which provided an opportunity to reevaluate the value of the project and to review our past efforts. We felt even more responsive in the actual production of recycled products, and found that our social interest has grown even more than before. It made us realize that our longstanding efforts match the current times.

Mitsuo Toya (“Toya”), who has extensive experience in the Technical Section of the Logistics Business Division, was also selected as a member of Taiyo Kogyo’s new EVA tarpaulin recycling project.

The goal was to use TAICON, which was destined to be discarded after 15 years of use, and make them shine as useful to society again.

This is a positive commitment to the SDG initiatives by Taiyo Kogyo as a leading company.

It was also an expression of their mission to pave the way for a better society.

Toya’s challenge also brought new value to the project and was an important step forward for the future.

Toya:

My career in the logistics engineering department has ranged from the designing of TAICON, material testing, product evaluation, and safety seminars for customers. Just as the EVA tarpaulin recycling project was getting underway, I was put in charge of material evaluation and technical support for the recycled EVA tarpaulin.

As a matter of fact, we have been implementing ideas such as recycling or upcycling products that have been in use for 15 years and transforming them into new products. However, the initial develppment was focused on the point of view of the Logistics Department. We had failed to achive the desired results, which made me nervous.

However, the General Manager proposed to recycle TAICON that had reached the end of their useful life as TAICON again, thereby reducing the cost of waste disposal and improving system efficiency. He concretely demonstrated what a leading company should look like. I personally found great value and significance in the process of recycling from TAICON to TAICON, rather than using an entirely new resource, and I moved forward with the realization of this proposal.

Diverse wisdom intermingles and enthusiasm fuses.

Leading specialists in the industry repaints the future of recycling.

The EVA tarpaulin recycling project gradually added diverse departments and outside collaborators to the team, eventually numbering about 20 members.

This innovative approach combines technology and knowledge honed in their respective fields.

The collective passion for success has resulted in a powerful driving force that has propelled the project forward.

Nakanishi:

The project gradually gathered members from diverse departments of our company, including our engineering and sales divisions, eventually numbering about 20 people. We also received cooperation from people from different industries, incuding our fabricators.

We set out to reform the recycling process and generate innovative ideas. Among those who renewed my enthusiasm was Mr. Yoshida, a sales representative. He has an exceptional ability to see things from a broad perspective. He connected us with plastics experts and researchers with PhDs in materials science, giving us the opportunity to gain the knowledge we needed to improve the quality of our recycled materials. The knowledge I gained from them led to a significant improvement in the quality of recycled materials and brought the project to life. And any hesitation I had was transformed. My motivation increased.

The catalyst for the project to move forward was always the connections and teamwork. Coordinating among members and sharing information about recycling was challenging, but the personal connections and knowledge built in the process proved to be a valuable asset in moving the project forward.

Taiyo Kogyo’s mission to recycle the future goes beyond mere reuse.

With a deep concern for the environment and a sincere contribution to society at their core, Toya and his members, leads sustainable development through the practice of the 3Rs, setting a new standard in the industry.

Toya:

Our recycling efforts are centered on the key values of social contribution and environmental protection. By practicing and embodying the spirit of the 3R principles of Reuse, Repair, and Recycle, we aim to establish ourselves as a leading company in the industry.

In this context, our team is working daily toward one major goal. That goal is to create valuable recycled products and provide them to our customers. This is more than just a job; it represents the pride of each member and their deep passion for their work. Through many repeated attempts and overcoming technical barriers and cost issues, we have achieved great growth. Each challenge further strengthens the bond of the entire team.

However, detailed management is required in terms of legal issues, proper handling of waste, and utilization of recycled resources. The process also entails commensurate costs, the justification for which must be carefully considered. Our efforts are not a simple smooth road, but a winding one at times. Nevertheless, we are working together as one to build a recycling process that works.

The steep road to establishing a recycling system.

Creating a new business model by combining advanced technology and extensive experience.

The road to recycling is steep and requires many steps.

However, Taiyo Kogyo’s in-house complete recycling process, sets an example for the industry, improving efficiency through a combination of technology and experience.

Future challenges are to integrate social contribution and environmental protection through the reuse and recycling of our products.

This will be a challenge towards a new business model.

Nakanishi:

Recycling TAICON when it is no longer usable requires a number of steps. We have a nationwide network that collects used materials, performs cleaning maintenance, disposal determination, simple cleaning, sorting, and sorting. We then turn the recyclable materials into new products and lead them through the recycling process to bring them back to life again.

This cycle is complex and requires a great deal of effort and time, but we have a cycle that allows us to complete these processes in-house. This allows us to do all of the work without relying on other companies, which gives us a significant advantage in the industry. Through the project, the General Manager gained a deep understanding of the importance of recycling permits, and the members of the company have used this knowledge to create their own system. This has greatly improved the efficiency and results of the recycling process.

We are considering a cycle whereby the recycled container bag resin is not only exported, but also reused as our own product, “TAICON”.

We also aim to make profits commensurate with our costs, and are striving to realize a better society through recycling as a new business model that contributes to society and protects the environment.

During the recycling process, there is a risk that foreign matter left in the recycled resin could damage expensive production equipment.

We are currently working with an outside subcontractor to find a solution.

This effort is not limited to the reuse of TAICON, but a contribution to the expansion of recycling culture in Japan.

Toya:

We plan to use machines to reprocess soiled material and make new products, but there is a risk that the debris in the material will damage the machines. If the machine malfunctions, it could cause significant damage, so we take considerable precautions.

In taking on this challenge, we have been working with several partner companies to find a solution, and through joint efforts and ingenuity, we are beginning to see clues to a solution to the problem. We have already begun to see the possibility of turning contaminated materials into something valuable again through cooperation with two partner companies. This cooperation is helping us to find new ways to create new recycled materials while protecting our facilities.

From Regeneration to Innovation.

A new business model that shapes discarded TAICON into new high-quality products sets the standard for recycling.

Breathing life back into used TAICON into new products

The challenge of the grand project still continues.

The project is still in its early stages, but the day is not far off when this revolutionary business model for recycling will take shape.

Nakanishi:

Through this model, we are now rethinking CO2 reduction, including recycling, and are developing our business in a flexible manner. Currently, we are about 70% complete in the hardware aspect of recycling from TAICON to TAICON. However, since TAICON is a product that is used for more than 10 years, we are at about 40% if we include the software side. Moreover, we believe that the key to whether the recycled products will be accepted by customers after reaching the goal is not only the sales force, but also the conceptual ability to communicate the excellence of this project.

According to the schedule, the goal is 2025. However, even upon completion, it is uncertain whether the recycled product will last 10 years, and it is imperative to prove that it has the same durability compared to today’s 15-year usable products. Testing is essential to evaluate the durability of a product in a short period of time, for example by using accelerated testing and applying a 15-year load in a few days.

Even if completed in this way, it does not necessarily mean success. It may take much longer than imagined to realize “TAICON from the cradle to the grave and to new life.” In fact, our challenge may be a never-ending journey with further updates after completion.

If this project is successful, it will bring us closer to completing an innovative business model to achieve our environmental goals.

A bold step toward a sustainable future.

The day is not far off when Toya and his team’s efforts will eventually have a global impact.

Toya:

The product is already taking shape, but we are facing numerous challenges to push its quality to new heights.

At first, I myself was not aware that this initiative had such great significance, but now I am deeply aware of its value and am passionately committed to it.

As the quality of recycled resin improves, it may open the way to new markets.

It is a step toward a sustainable future, and our efforts have the potential to impact the world at large. We hope you will join us.

Taiyo Kogyo will continue to keep up with the times.

To grow existing businesses, protect the environment, and contribute to creating a better society.

Since the 1960s, Taiyo Kogyo has utilized membrane material technology to contribute to the evolution of the logistics industry. By changing the shape of logistics from paper bags to container bags and facilitating mass transportation, Taiyo Kogyo provided running-type TAICON that boasted the No. 1 market share in the industry. This promoted rationalization and efficiency in logistics. Furthermore, we are focusing on recycling business, rental business to meet fluctuating transportation demand, and technological development to improve work efficiency. We will continue to build a better future by creating a new business model with environmental protection and contribution to society at its core.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Recycling container bags (TAICON) into plastic moldings. Taiyo Kogyo’s innovations weave a sustainable future.