MakMax Plus

Necessity of installing anti-scattering tents at contaminated soil remediation construction sites.

2020.09.09

When performing contaminated soil response work, some sites require tents for a variety of reasons. There are diverse types of tents for different uses, and the right type of tent must be installed.

This article describes anti-scattering tents, which are required at sites where scattering of contaminants may occur. In what situations are shatterproof tents needed? What kind of tent is needed and what features should we look for?

For those involved in the subject field, please refer to the contents of this article.

Table of Contents

1 Contaminated Soil Response Works and “Soil Contamination Countermeasures Law

2 Construction work to deal with contaminated soil that requires anti-scattering measures

2-1 In-situ treatment of contaminated soil and temporary storage of contaminated materials

2-2 Treatment at Contaminated Soil Treatment Facilities

3 Taiyo Kogyo’s scattering prevention tent for soil contamination control

3-1 Structure for easy moving and relocation

3-2 Extensive lineup to protect the work environment

3-3 Sizes available upon request

3-4 Pillarless space ideal for indoor work

3-5 Bright membrane space allowing natural light to penetrate

4 Conclusion

Contaminated Soil Remediation Work and "Soil Contamination Countermeasures Law

Contaminated soil refers to soil (soil) that contains specified hazardous substances in excess of standard values. Because of the potential for adverse effects on human health and living organisms, hazardous materials and soil itself must be treated using appropriate equipment and measures in construction projects that handle them. This work is called contaminated soil remediation work.

There are many different types of hazardous materials. Therefore, there are multiple types of contaminated soil, and appropriate treatment methods are determined for each type of soil. The “Soil Contamination Countermeasures Law” established the rules for this. The purpose of this law is to determine the status of soil contamination and to prevent human health hazards caused by soil contamination. The law defines the criteria for land that is subject to the obligation of soil contamination investigation, as well as the specific hazardous substances to be covered and their standard values.

In accordance with the “Soil Contamination Countermeasures Law,” specific equipment may be required to properly treat contaminated soil, as the construction work is required to be carried out using treatment methods that match the characteristics of the contaminated soil. One of these facilities is a tent. Tents used for contaminated soil response work are primarily intended to protect the site environment, ensure worker safety, and store contaminated materials.

Contaminated soil remediation work requiring anti-scattering measures

The role of tents for contaminated soil control is to prevent the dispersal of contaminants. Because contaminated soil response work deals with hazardous materials, strict measures must be taken to avoid any impact on the surrounding environment. As one of the responses, there are cases where anti-scattering measures are required depending on the contaminated materials handled.

Identify situations where anti-scattering measures are required in contaminated soil remediation work.

In-situ treatment of contaminated soil and temporary storage of contaminated materials

Cases where anti-scattering measures are required include those where contaminated soil is to be treated in-situ or where contaminated materials must be temporarily stored.

Excavation of contaminated soil brings to the surface toxic substances and soil contained in the ground, which must be dealt with to prevent them from being dispersed.

Treatment at contaminated soil treatment facilities

In addition, contaminated soil treatment facilities must also take measures to prevent scattering, depending on the treatment method. One such example is the extraction and removal of hazardous materials by magnetic sorting at purification and other treatment facilities. Magnetic sorting is a method of removing specified hazardous substances by mixing magnetic adsorbent (iron powder, etc.) with soil, causing the specified hazardous substances to be adsorbed by the iron powder, etc., and then collecting the adsorbent with a magnet or similar device. In the case of the “dry method,” the soil must be adequately dried, so the drying equipment must be equipped with anti-scattering measures.

(*This applies to Class II Specified Hazardous Substances excluding boron. When handling mercury, volatilization must be taken into account.)

The standards for treatment facilities are set forth in the “Standards for Contaminated Soil Treatment Facilities (Article 4, No. 1 of the Ministerial Ordinance on Treatment Business). The purpose of these standards is to prevent the spread of contamination outside the facility and to ensure that the facility functions properly to treat contaminated soil according to the amount and state of contamination handled.

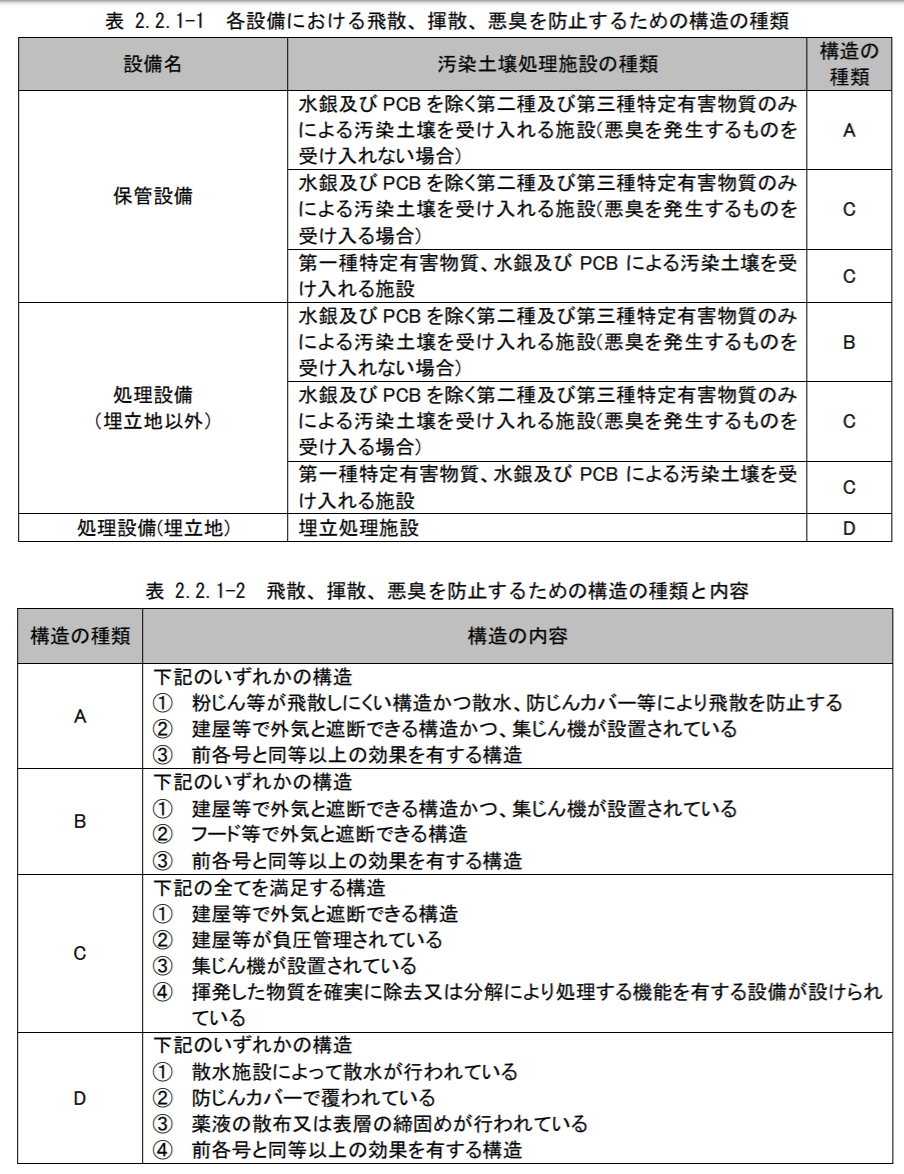

Specifically, it is agreed that the structure of the facility must be designed to prevent dispersal, underground seepage, and emission of odors, or that facilities necessary for prevention must be provided. For example, Class I Specified Hazardous Substances, mercury, PCBs, and other materials are considered to be a concern for atmospheric dispersion, so the facility structure or preventive equipment must be maintained and managed to ensure that it functions properly.

Specific standards have also been established to ensure that contaminated soil is not dispersed when it is moved within the treatment facility.

(Source: Ministry of the Environment, Technical Considerations for Permit Examination of Contaminated Soil Treatment Business)

Taiyo Kogyo's scattering prevention tent for soil contamination control

In order to properly implement the prevention of contaminated soil dispersal, the site environment must be created with appropriate equipment. The equipment that can be utilized for this purpose is a shatterproof tent. Compared to general construction, tents offer a high degree of versatility and convenience, as they can be used for outdoor work or indoors, such as in treatment facilities. Here, we take as an example a scattering-prevention tent for soil contamination countermeasures by Taiyo Kogyo Corporation, which has been involved in membrane structures for about 100 years.

Taiyo Kogyo’s tents can be utilized in a variety of sites, as we manufacture membrane structures with free design and high design quality, taking into consideration the purpose and the environment. The scattering-prevention tents are the culmination of the company’s know-how and are equipped with optimal functions for preventing contaminants from scattering into the surrounding area. The main features are as follows

Structure for easy moving and relocation

The roof unit can be moved by crane or winch to accommodate large areas. The structure also facilitates relocation of large-span facilities (W15 to 30 meters), thus reducing costs.

Extensive lineup to protect the work environment

The facility can also accommodate the necessary equipment to prevent contaminants from being carried outside, such as a tent in the front room for temporary waiting areas for work vehicles, screening rooms, negative pressure dust collectors, etc. Screening rooms are equipped with air showers and changing rooms, etc. to prevent dispersal of contamination and contamination to workers and ensure safe management of the work environment. Negative-pressure dust collectors can discharge air containing dust as clean air through multiple high-performance filters.

Sizes can be accommodated on request

There are four types of frontage: 15m, 20m, 25m, and 30m, and the depth is available in 2m increments to meet your needs.

Pillarless space ideal for indoor work

The bolt-on frame type structure, which does not use columns, makes it possible to maximize area and create space for flexible layout. In addition, assembly and disassembly can be performed in a short period of time using a large crane.

Bright membrane space allowing natural light to penetrate

The entire roof is made of a thin membrane material, allowing natural light to penetrate through and be captured, ensuring the brightness of the working space inside the tent. It also saves energy by reducing the number of lighting fixtures.

summary

In many cases, contaminated soil and the dispersal of contaminated materials must be prevented. Since this is a legal requirement, it is necessary to comply with the exact rules and regulations. Taiyo Kogyo’s scattering prevention tents not only meet the minimum requirements of such rules, but also provide high functionality and convenience.

If you are considering measures to prevent the dispersal of contaminated soil, please contact Taiyo Kogyo first.

Official Website: Taiyo Kogyo Corporation

Tent Warehouseへの

Any Inquries

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

Recommended for

I don't know where to start in building a warehouse.

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- MakMax Plus>

- Necessity of installing anti-scattering tents at contaminated soil remediation construction sites.