MakMax Plus

When is a tent required at a construction site for mercury, PCB, and dioxin contaminated soil remediation?

2020.09.09

The method of treatment and equipment required for contaminated soil remediation work depends on the type of contaminants contained in the ground. This section explains what construction methods are required at response construction sites that handle the typical contaminants of mercury, PCBs, and dioxins, and what equipment is required for each method.

Finally, we will also provide specific tent details, so if you are considering construction, please refer to this information and make appropriate preparations and responses to suit your site.

Table of Contents

1 Typical pollutants and laws governing their response

2 Treatment methods for soil contaminated with mercury, PCBs, dioxins, etc.

2-1 VOC Treatment Method (1) “Hot Soil Method

2-2 VOC treatment method (2) “In-situ bioprocessing

2-3 Soil treatment methods for mercury, PCBs, and dioxins (1) “Excavation and removal method

2-4 Soil treatment method for mercury, PCBs, and dioxins (2) “On-site treatment (purification) method

3 Organizing cases where tents are needed for treatment of contaminated soil

4 Tents and temporary roofs used in soil remediation work for PCB, mercury, and dioxin contaminated soil│Taiyo Kogyo’s lineup

4-1 Shatterproof tents

4-2 Dust diffusion prevention tent containing hazardous materials

4-3 Telescopic tents

4-4 New type telescopic temporary tent

4-5 Fixed Tents

5 Conclusion

Typical pollutants and laws governing their response

First of all, contaminated soil is soil (soil) that contains specific toxic substances in excess of the standard values. Contaminated soil poses a risk of adverse effects on human health and other living organisms due to direct ingestion of soil or ingestion of groundwater leached from soil, etc. Therefore, it was deemed necessary to take countermeasures, and a law was created to provide detailed regulations on these measures.

This is the Soil Contamination Countermeasures Law, which was enacted in 2003 (with major revisions in 2010). (This law aims to prevent human health hazards caused by soil pollution and to understand the status of soil pollution. When implementing countermeasure works for contaminated soil, it is required to comply with this law.

There are many different types of contaminants that are the subject of contaminated soil. Three typical examples are as follows

- mercury

- PCB (polychlorinated biphenyls)

- dioxin

Mercury is the only metal that is liquid at room temperature and was the cause of the famous Minamata disease, and if mishandled, can have a significant impact on the human body and the surrounding environment.

Polychlorinated biphenyls (PCBs) are highly toxic substances that were once contained in insulating oils used in transformers (transformers) and capacitors (capacitors). Due to the damage caused by the toxicity of PCBs, the “PCB Special Measures Law” was enacted, which obliges storage operators to properly dispose of PCBs by 2027.

A total of 223 chemicals with similar properties are collectively referred to as dioxins. In some cases, dioxins are produced and contaminated when incinerated ash is buried in the soil at former factory sites. In order to deal with such cases, the Law Concerning Special Measures against Dioxins was enacted to establish standards and regulations concerning dioxins and to take appropriate measures.

Treatment methods for soil contaminated with mercury, PCBs, dioxins, etc.

The following is an explanation of specific treatment methods for soil contaminated by typical contaminants such as mercury, PCBs, and dioxins. There are multiple types of treatment methods, which are categorized into the following construction methods (The conditions for requiring or not requiring a tent differ for each construction method, so confirmation is required.

VOC Treatment Method (1) "Hot Soil Method

This method involves mixing quicklime and other materials with soil contaminated with VOCs (volatile organic chlorinated compounds) and using the reaction heat to volatilize, separate, and adsorb the VOCs using activated carbon. A tent is required for this method of construction in situ.

VOC treatment method (2) "In-situ bioprocessing

This is a method of purifying VOCs and oil that can be decomposed in-situ without excavation by activating decomposing microorganisms with nutrient salts and highly concentrated oxygenated water using a simple chemical injection system. No tent is required for this method. Other methods include on-site injection of chemicals.

Soil treatment methods for mercury, PCBs, and dioxins (1) "Excavation and removal method

This method involves excavating and removing contaminated soil directly at the site and transporting it to an off-site intermediate treatment plant. Basically, a tent is required, but this may or may not be necessary depending on the type of contaminated material.

Soil treatment method for mercury, PCBs, and dioxins (2) "On-site treatment (purification) method

This method involves bringing in a purification plant on site and treating the waste. As with the “mining removal method,” a tent is basically required.

Organizing cases where tents are needed to treat contaminated soil

It was confirmed that the need for tents varies depending on the contaminants handled and the method used to treat them. The following is a summary of the cases in which tents are required to treat contaminated soil.

- In cases where excavation and removal methods are used for VOC-contaminated soil, tents are required to protect the soil from rain and dust.

- When handling mercury, PCBs, dioxins, and POPs, a tent with a front room that can control negative pressure is required in principle.

- For other heavy metals, tents are used when it is necessary to take measures to protect the neighborhood.

- In cases where the hot soil method is used and work is performed in situ, a tent is required.

- Care should be taken with the excavation and removal method, as the need for tents varies depending on the type of contaminant.

- The “shear” generated by tunnel excavation may produce naturally occurring toxic substances (8 types except cyanide). Tents are less necessary except for mercury due to heavy metals, but if rain protection (drying/temporary storage of soil) is required, it is preferable to install tents.

Tents and temporary roofs used in soil remediation work for PCB, mercury, and dioxin contamination│Taiyo Kogyo's lineup

In the previous section, we introduced the cases in which tents are required. However, there are many different types of tents, depending on their intended use. The specific types of tents must be understood and used according to the site.

The following is an example of the lineup of tents manufactured by Taiyo Kogyo Corporation. This section introduces the types and features of tents (temporary roofs) so that you can choose the best tent for the contaminant you are handling and the method of contaminated soil construction.

Shatterproof Tent

Taiyo Kogyo’s tents (membrane structures), which boast high design quality and freedom of design with consideration for the purpose and environment, are used in a variety of contaminated soil remediation projects, including contaminated soil treatment, temporary storage of contaminated materials, and indoor final disposal sites.

The “scattering prevention tent,” which brings together all of this know-how, is a high-quality tent that functions well in preventing contaminants from scattering into the surrounding area. Moving can be done smoothly, and the roof unit can be moved with a crane or winch to accommodate large areas. The structure is designed for easy relocation even for large-span facilities (W15 to 30 meters), contributing to cost reduction.

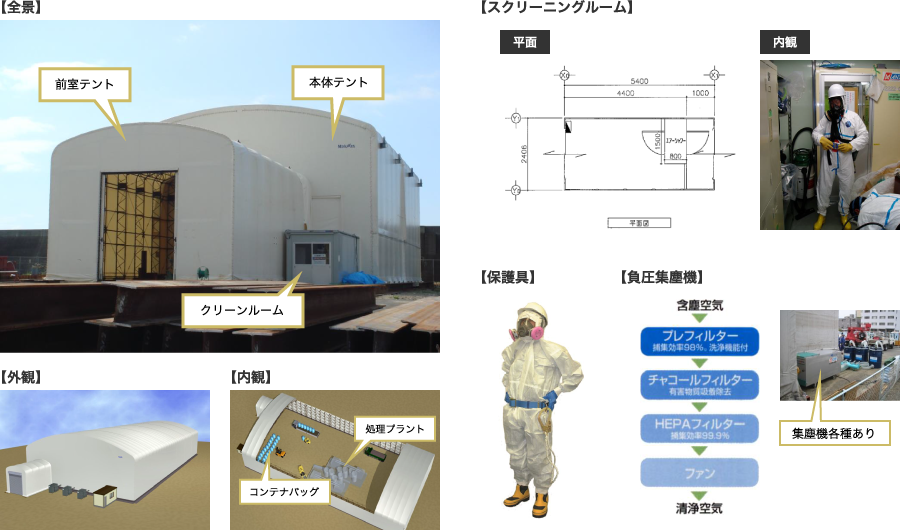

Tents to prevent the diffusion of dust containing hazardous materials

The Hazardous Substance Dust Diffusion Prevention Tent is a tent with a lineup of protective clothing to meet the requirements of each site, from Level 1 to Level 3, and a variety of environmental equipment and facilities to protect workers during contaminated soil remediation work.

Each product is a highly reliable set of products made with worker safety as the top priority, and can be constructed in optimal combinations to suit site conditions and situations.

Telescopic Tents

As the name suggests, a “telescoping tent” is a type of tent in which the tent itself can be expanded and contracted by means of a bellows structure. These versatile tents can be adjusted to suit the shape and condition of the site, the nature and progress of the work required, and even long or heavy items can be entered and exited directly by crane with a wide frontage. No machinery is needed to expand or contract the shed, and the convenience of being able to move it manually is also provided. Five frontage sizes are available.

Installation can usually be completed in 1 to 4 days per building, and removal can usually be restored to its current condition in 1 to 2 days.

New Telescopic Temporary Tent

The “New Telescopic Temporary Tent,” which is telescopic with a structure that allows the tent to be inserted span by span, can be rented only for the area needed. Since the tent can be inserted span by span, the dimensions in the girder direction can be freely set for each span (1.5 m).

The opening is curtain-type and fully opens by simply sliding it open, enabling speedy loading and unloading and improving work efficiency. Tent installation is simply a matter of inserting and sliding the split membrane along the guide fasteners, which is a key point of improved construction and safety compared to the previous model.

Fixed Tent

Unlike the telescoping tents mentioned above, fixed tents cannot be flexibly adjusted in size, but they are fixed-size tents that can easily provide a large storage space. It can be built in a short period of time as a fully functional storage warehouse. Featuring a large space with no intermediate posts and a generous 7.5 m eave height, this tent is ideal for sites that need to store plenty of cargo.

Since the structure complies with the Building Standard Law, it is possible to apply for a building permit.

summary

Contaminated soil measures vary in content. Many may feel that there are many precautions to be taken, as appropriate measures must be taken for each site. If you need a tent, you need to choose the right tent, but the variety of tents available makes it difficult to know what the best fit is.

Taiyo Kogyo Corporation also produces a large number of tents for contaminated soil remediation, and has the lineup and responsiveness to meet the needs of any site. If you are considering a tent, please contact us.

Tent Warehouseへの

Any Inquries

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

Recommended for

I don't know where to start in building a warehouse.

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- MakMax Plus>

- When is a tent required at a construction site for mercury, PCB, and dioxin contaminated soil remediation?