Tetrafluoroethylene resin

Coating film (PTFE film)

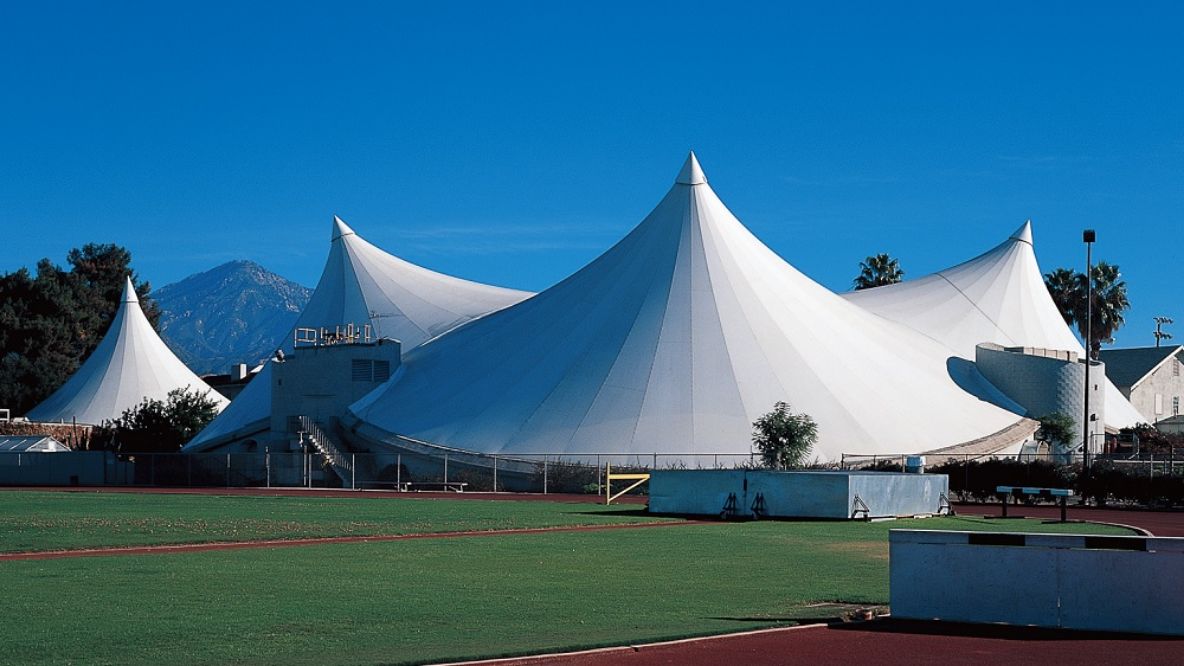

University of La Verne (USA)

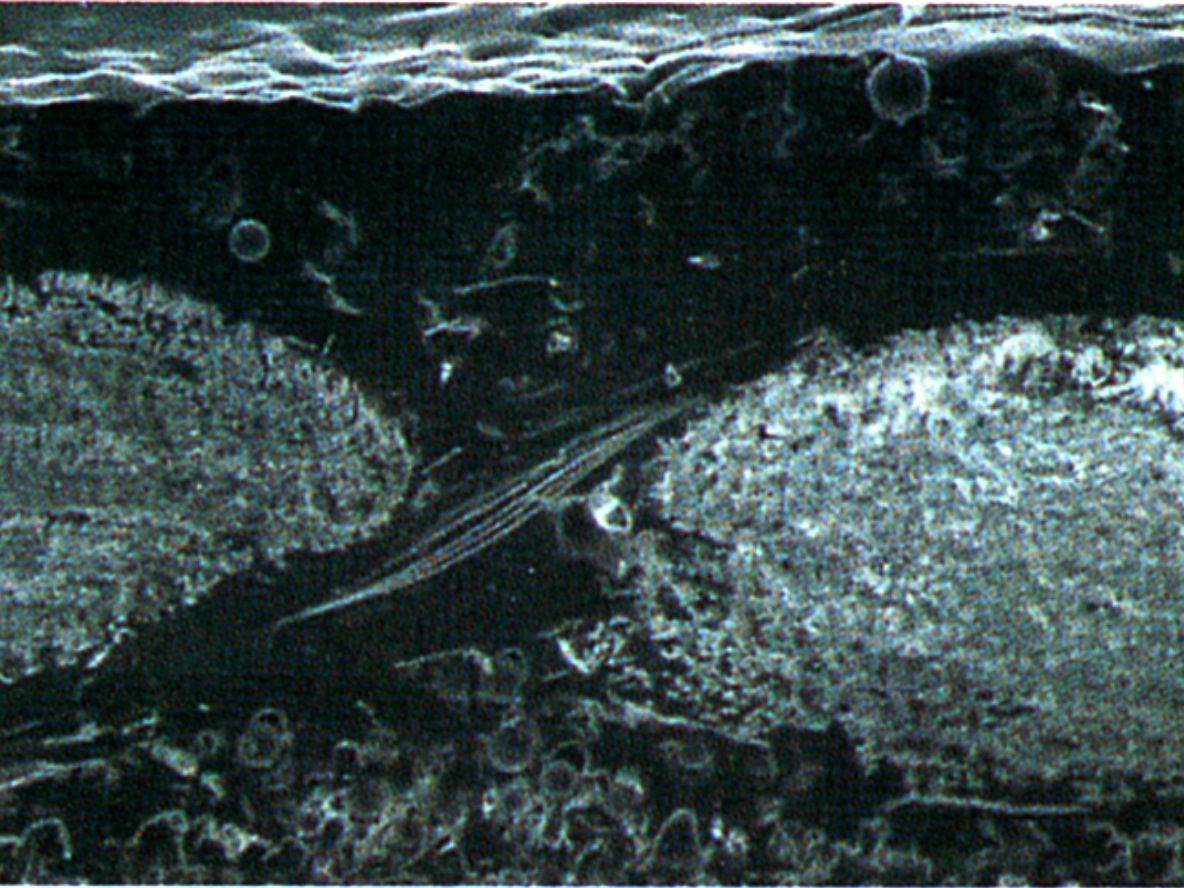

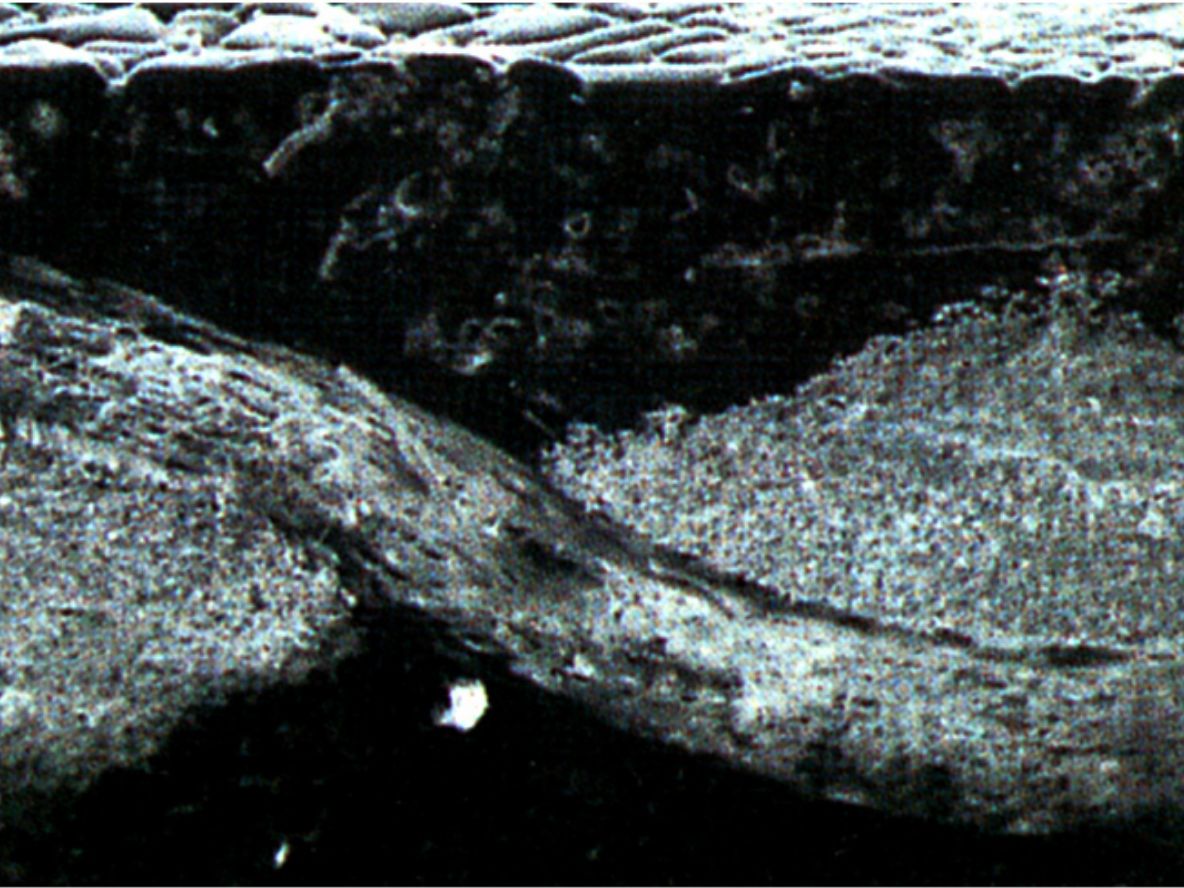

The tetrafluoroethylene resin-coated membrane (PTFE membrane) was used in the world's first permanent membrane structure building, the University of La Verne (constructed in 1973). Comparing a cross-sectional view of a membrane sample from the time of construction with a current membrane sample using micrographs, there is no noticeable deterioration. In addition, there is no change in stain resistance, color tone, translucency, or woven fabric protection, demonstrating its excellent durability.

Sample micrograph from 1973 (60x)

Micrograph of a sample taken from the current University of La Verne (60x)

*The membrane material used at the University of Laverne was a Chemifab (now Saint-Gobain) product, which is a fiberglass vater yarn from Ones Corning Fiberglass coated with DuPont's tetrafluoroethylene resin.

Features of tetrafluoroethylene resin coated film (PTFE film)

antifouling property

The fluoroplastic surface is highly water-repellent and prevents the adhesion of dirt and dust. Even if they adhere temporarily, they are washed away by rain and retain their beauty for a long time.

incombustibility

A membrane material combining self-extinguishing PTFE and heat-resistant woven glass fiber, which is certified as a noncombustible material.

translucency

Natural light entering the building through the fluorine membrane material is dispersed as diffused light, creating a softly lit space with few shadows.

Thermal Barrier

Fluoropolymer materials reflect most of the sunlight, thus reducing the amount of solar heat that enters the building.

ultra-lightweight

At only 350 g/m2 (200 μm thick), it is a very lightweight building material compared to other common building materials. As with conventional membrane-structured buildings, it reduces the burden on the building frame and improves earthquake resistance.

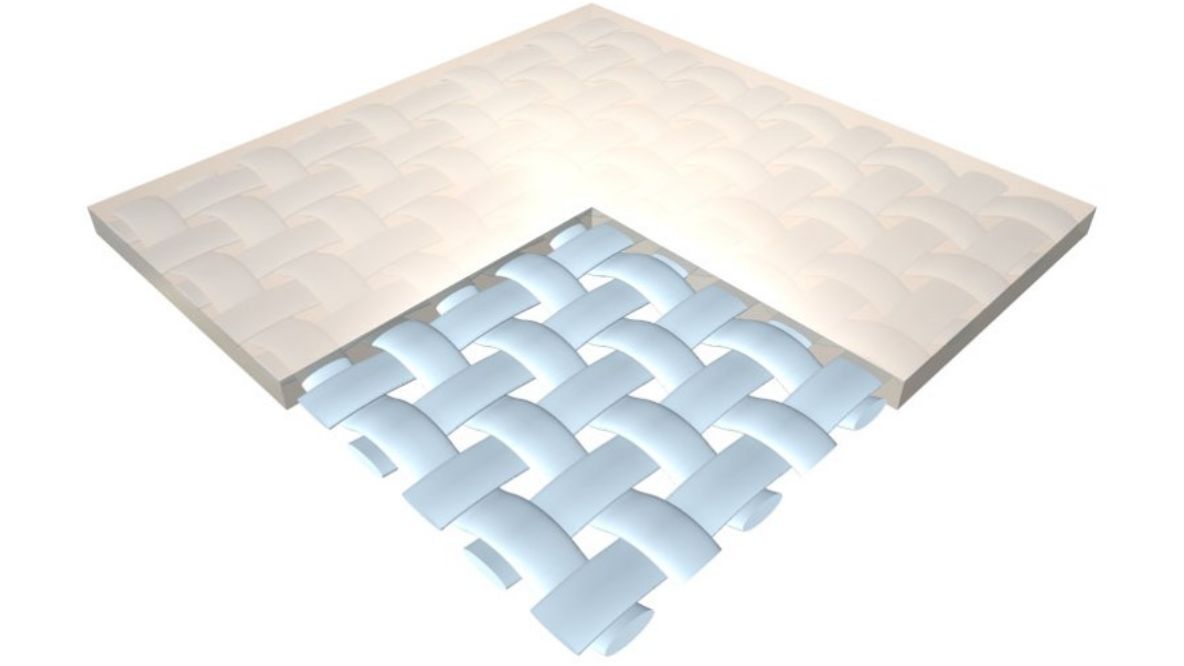

Membrane composition

Membrane surface

PTFE membrane material consists of a composite material of glass fiber fabric coated with fluorocarbon resin.

- TOP>

- Business & Products>

- Features of Membrane Structural Buildings>

- Tetrafluoroethylene resin coated film (PTFE film)