Features of Membrane Structural Buildings

Membrane buildings have many features that enrich people's lives and the environment by taking advantage of the lightweight and high strength of the materials.

Large-span liberating space can be realized.

Membrane materials are extremely lightweight compared to conventional building materials. Taking advantage of this lightness, membrane buildings can realize vast spaces with no pillars.

Bright space created by high light transparency

The use of white membrane materials keeps the room bright during the day and reduces lighting costs. In addition, lighting creates a fantastic space at night.

Shortened construction period

Large areas of membrane panels can be installed at once using the latest construction methods. Similarly, removal work can be easily performed.

Contributes to cost reduction

The lightweight materials used in the construction of the building reduce construction costs. White membrane material also contributes to lighting cost reductions due to its high light transmittance.

Material that combines high strength and flexibility

Membrane materials that have passed rigorous strength tests can be used in a wide range of specifications while maintaining high strength and durability.

Suppresses temperature and blocks UV rays

The white membrane roof has a high solar reflectance of more than 75%, which is equivalent to the high reflectance coatings typical of cool roofs. This results in a good thermal environment in the space covered by the membrane roof. In addition, because it significantly reduces ultraviolet rays, it creates a safe space for those who are concerned about the effects of ultraviolet rays.

Beware of wind and snow

Did you know that more than a dozen floating piers with membrane roofs are currently in use around the Okinawa Islands in the typhoon Ginza area? This is because membranes are resistant to salt damage, have excellent durability, and their light weight gives them an advantage in the structure of the floating pier itself. Regarding durability against strong winds, membrane materials certified as building materials have high strength, and by designing in accordance with the Building Standard Law, a membrane structure building will be strong enough to withstand typhoons.

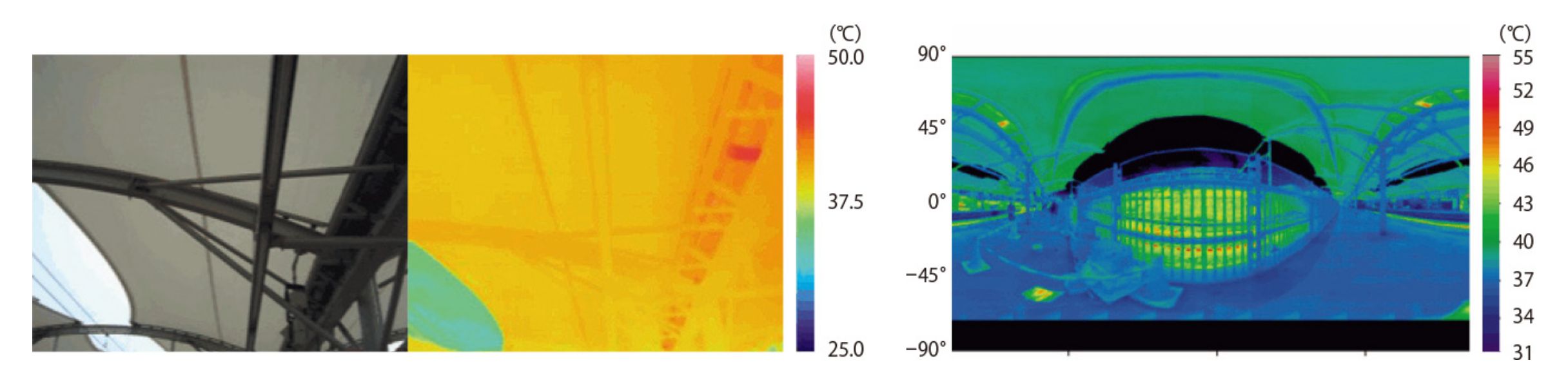

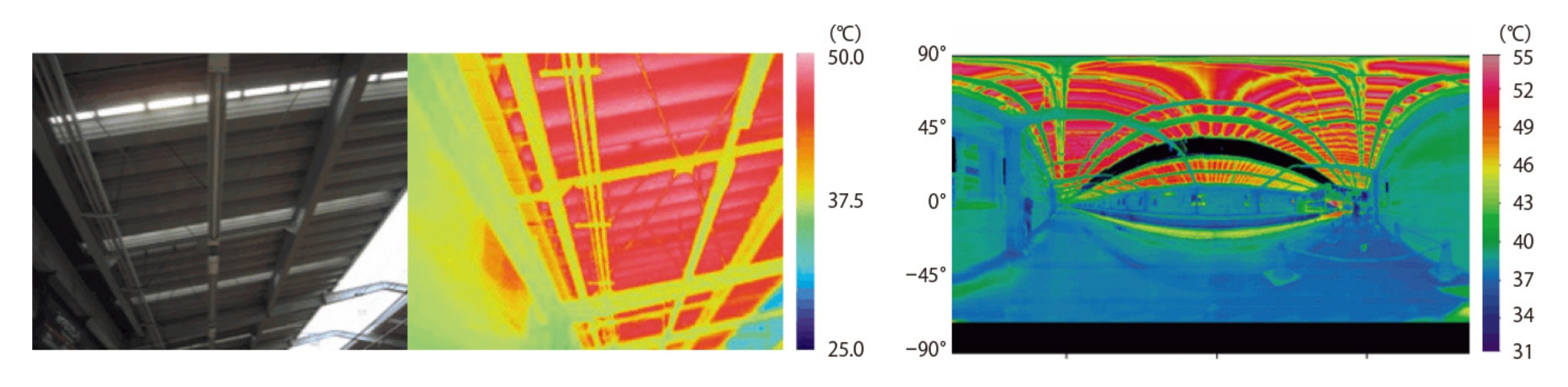

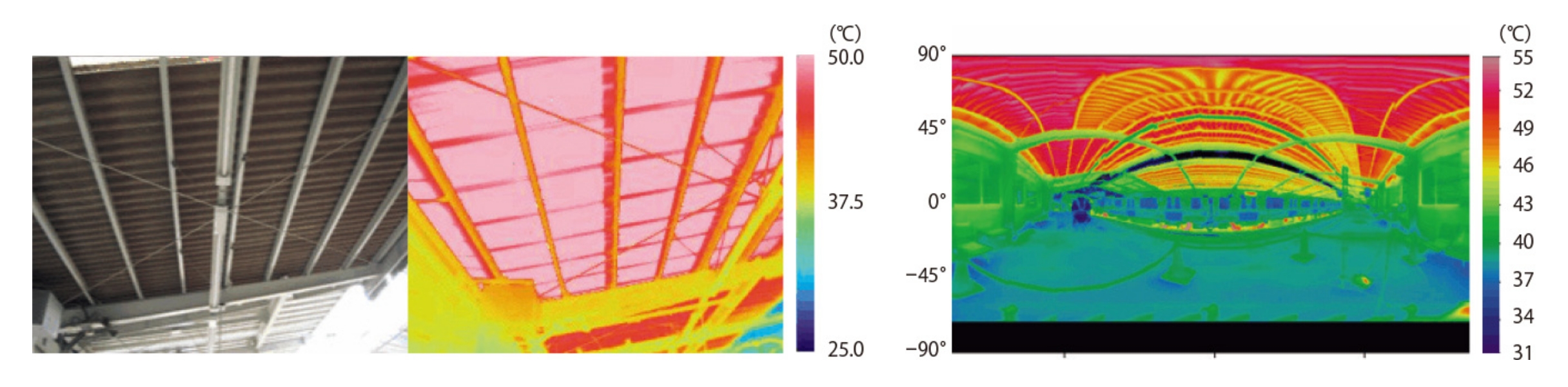

Attic surface temperature by material and

wind-chill index (factor)

The surface temperature under the roof, mean radiant temperature (MRT), and the temperature experienced under the roof due to radiant heat (OT) were measured for three types of roofing materials: membrane, metal, and slate.

As a result, it was confirmed that membrane roofs have a lower sensory temperature by 1.5°C compared to metal roofs and by 3.5°C compared to slate roofs.

The maximum illumination was 16,000 lx, which is much brighter than that of metal and slate roofs.

membrane roof

気温:35℃/屋根裏面温度:40℃

平均放射温度{MRT}:37℃/体感温度{作用温度OT}:36℃

最大照度:16,000lx

metal roof

Air temperature: 35°C / Attic surface temperature: 49°C

Average radiant temperature {MRT}: 40 °C / sensory temperature {action temperature OT} : 37.5 °C

Maximum illumination: 4,700lx

slate roof

Air temperature: 37°C / Attic surface temperature: 55°C

Average radiant temperature {MRT}: 42 °C / sensory temperature {action temperature OT} : 39.5 °C

Maximum illumination: 2,400 lx

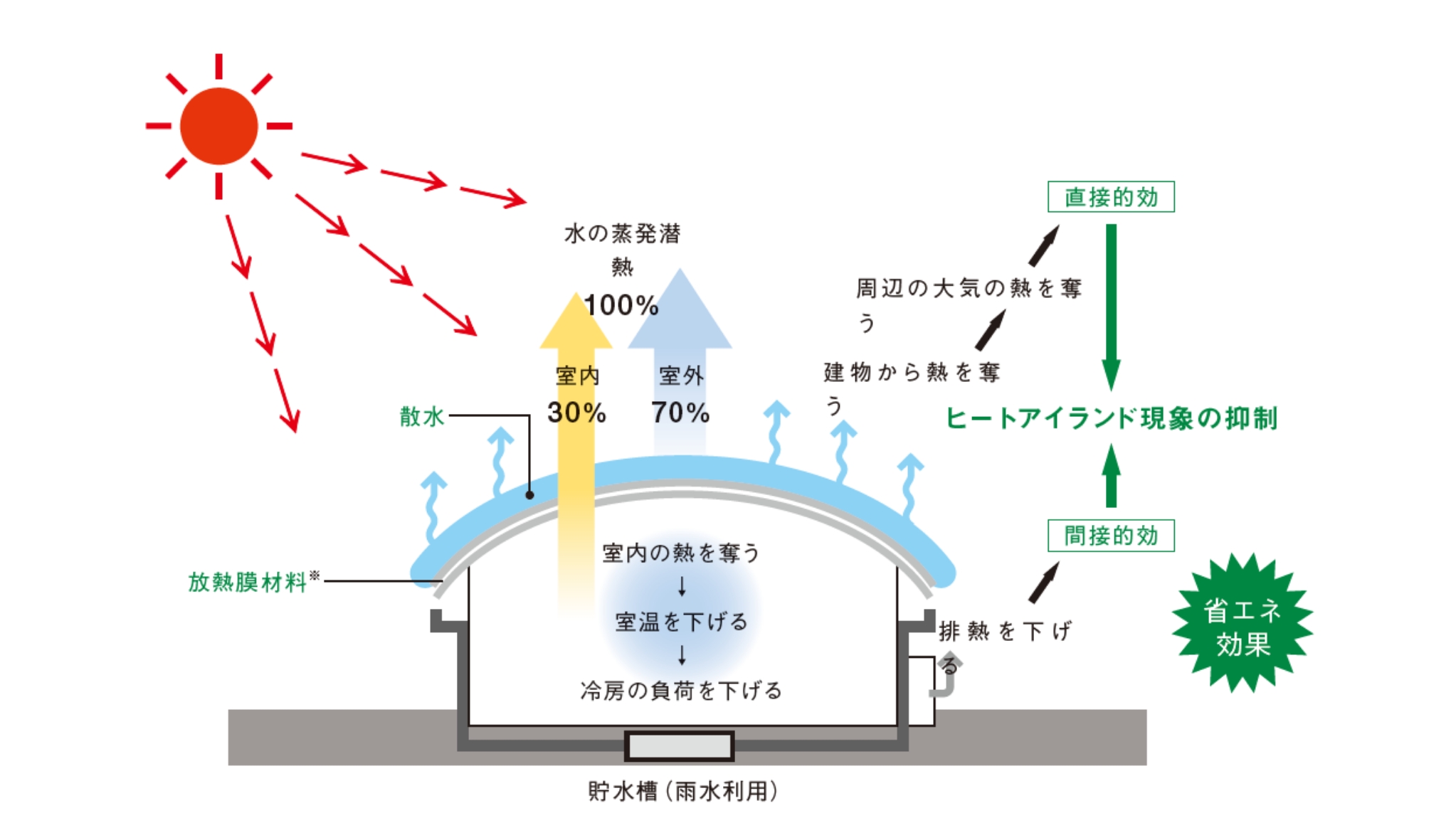

Also contributes to the reduction of the heat island effect

Membrane roofs have high solar reflectance, which increases the rate at which solar energy is reflected back into the sky and prevents heat absorption. This helps mitigate the urban heat island effect.

Reduction of CO2 emissions

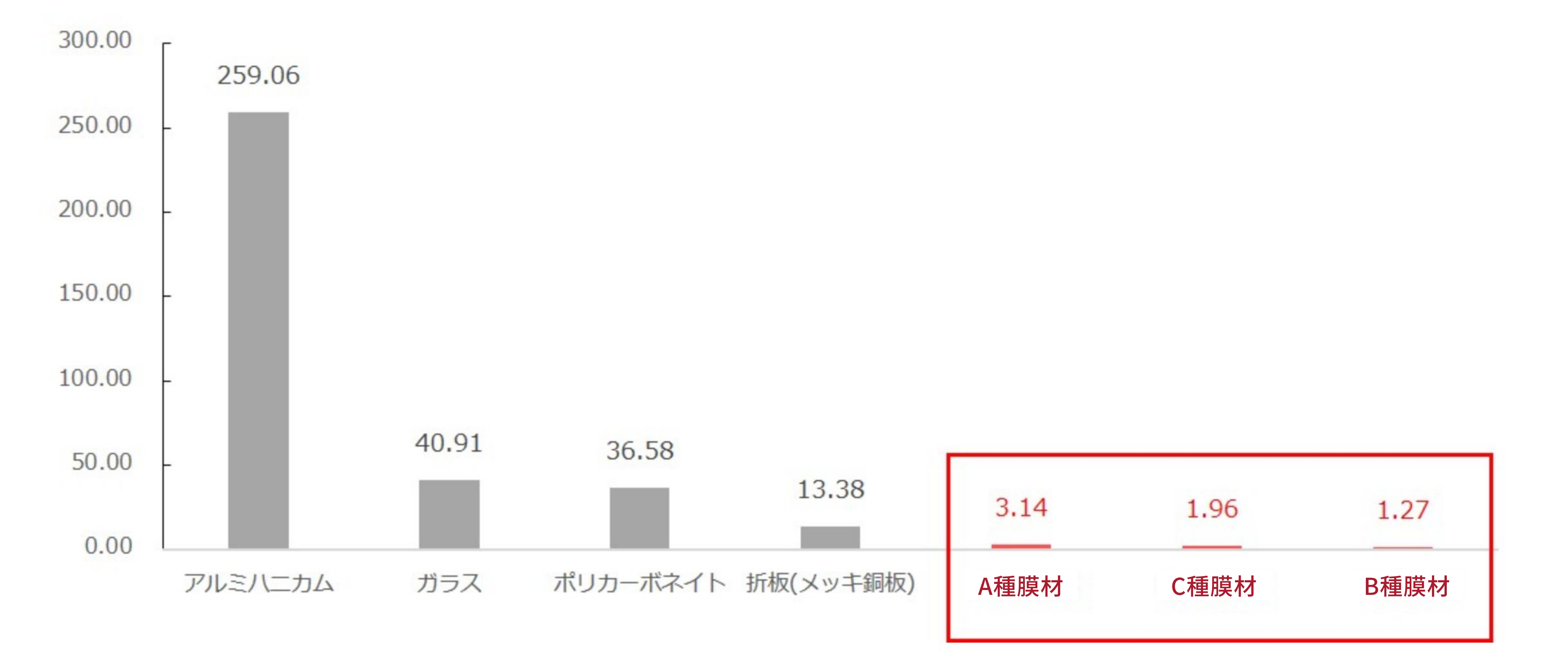

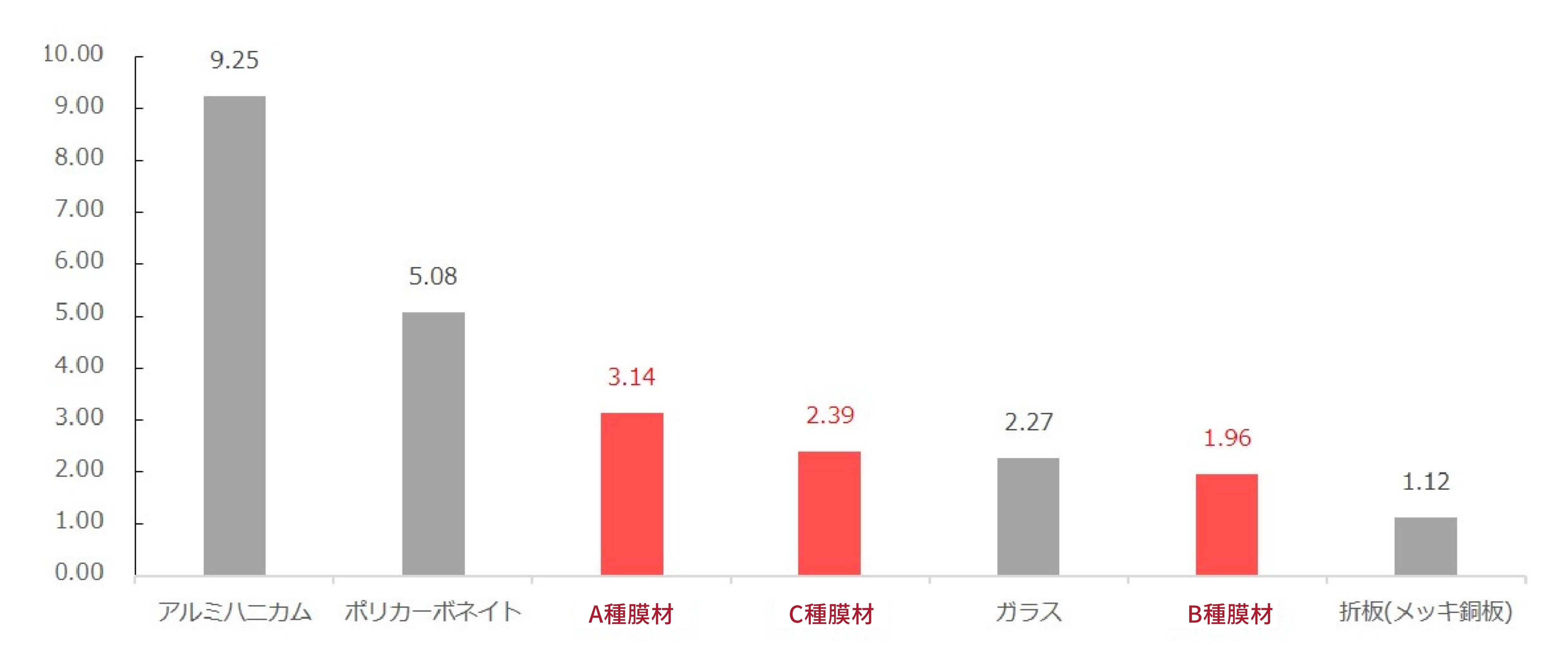

The CO2 emissions of membrane materials are calculated based on CO2 emission units* and compared with the actual use of the material as a building material,

The CO2 emissions per square meter of membrane material are approximately 3 kg-CO2/m2 (for Class A membrane material), which is by far the smallest amount compared to other materials.

The secret lies in the membrane material's overwhelming lightness as a building material, at approximately 1 kg per square meter.

Comparison in terms of CO2 emissions per square meter of building material ( kg-CO2/m2 )

Calculation conditions

| Material name | |||||||

|---|---|---|---|---|---|---|---|

| Aluminum honeycomb | glass | polycarbonate | splint Plated steel plate |

Type A (blood, influenza, hepatitis, etc.) membrane material |

Type C (hepatitis, etc.) membrane material |

Type B (blood, influenza, hepatitis, etc.) membrane material |

|

| Thickness (mm) | 105 | 6.8 | 6 | 0.8 | 0.6 | 0.54 | 0.54 |

| CO2 emission intensity ( kg-CO2/kg ) |

9.25 | 2.27 | 5.08 | 1.12 | 3.14 | 2.39 | 1.96 |

| Weight kg/m2 | 28 | 18 | 7.2 | 12 | 1 | 0.82 | 0.65 |

| CO2 per square meter amount of discharge ( kg-CO2/㎡ ) |

259.06 | 40.91 | 36.58 | 13.38 | 3.14 | 1.96 | 1.27 |

CO2 emission intensity of polycarbonate is based on "Chemical Economics Research Institute 1993".

CO2 emission intensity of other materials (production to distribution stage) is calculated by our company based on the "1995 Three Banks' Consolidated Review".

Comparison in terms of CO2 emissions per kg of building materials ( kg-CO2/kg )

Membrane materials weigh only 1 kg per square meter while other building materials weigh 7~28 kg per square meter. This leads to a significant reduction in CO2 emissions.

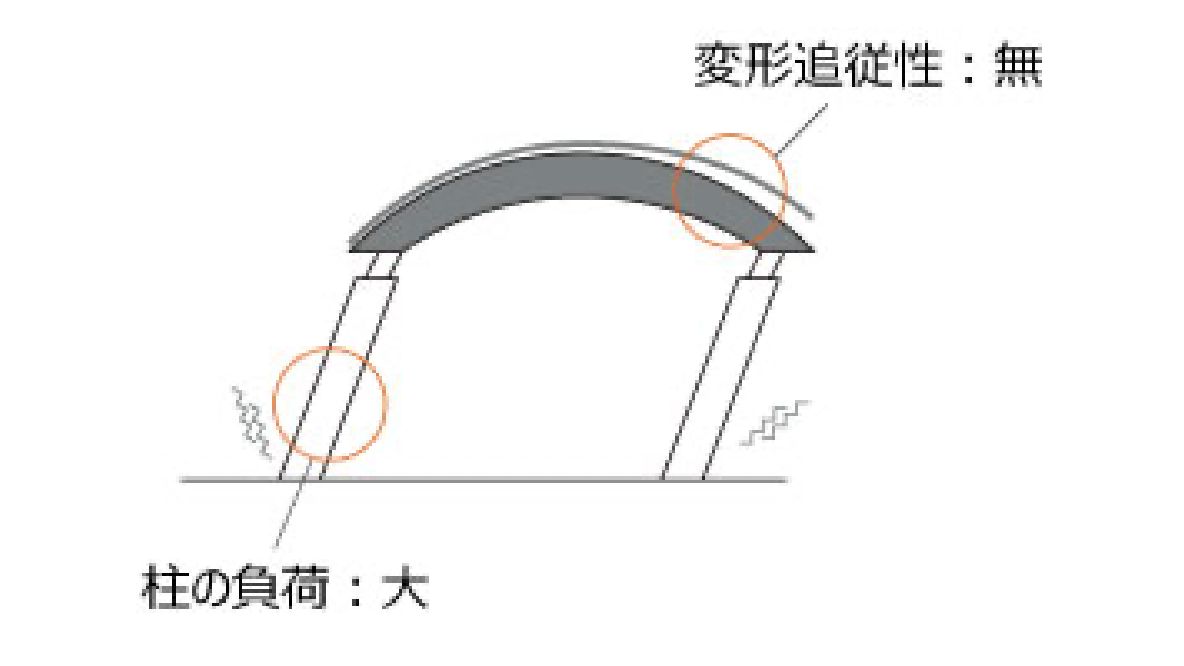

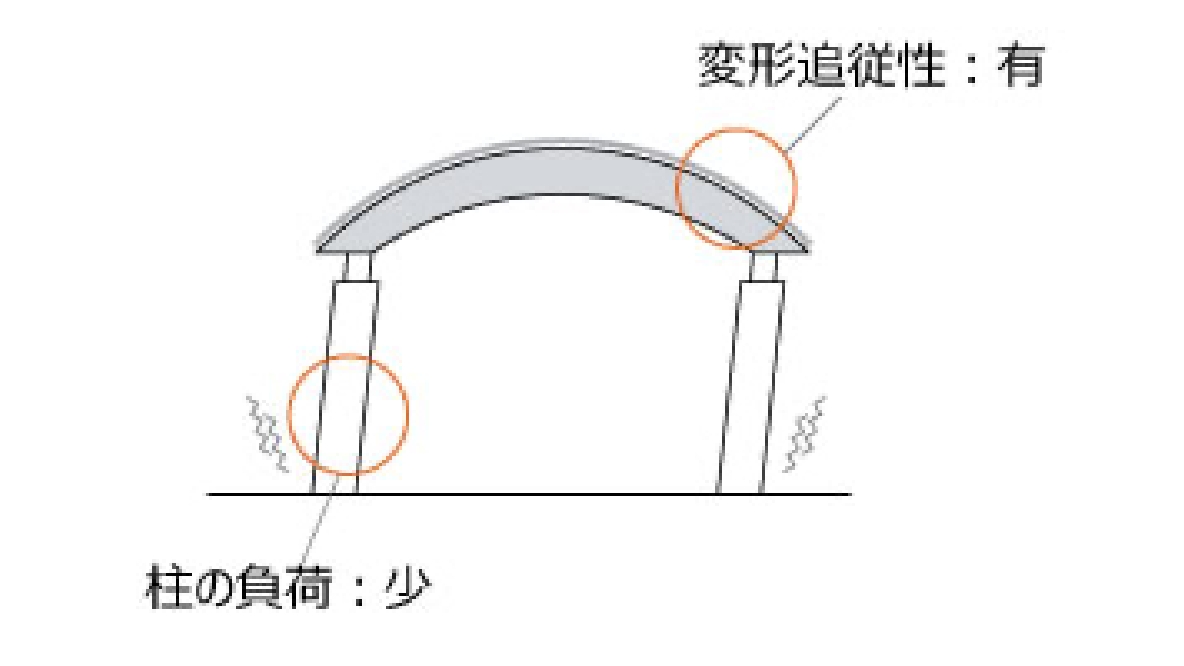

earthquake-resistant

Membrane materials are extremely lightweight compared to conventional building materials. This lightness is also very advantageous in the event of earthquakes.

Since the seismic energy of an earthquake is proportional to the weight of the roof, the lightness of the membrane material significantly increases the earthquake resistance of the building.

In addition, flexibility, one of the characteristics of membrane materials, allows them to follow deformation during earthquakes, making them less prone to breakage and shattering. It can be said that this material is less likely to cause secondary disasters due to falling.

metal roof

Prone to fall and collapse due to damage

Prone to secondary damage from falling objects

membrane roof

Rupture is unlikely to lead to immediate fall

Less likely to cause secondary damage from falling objects

Four basic types of architectural membrane materials

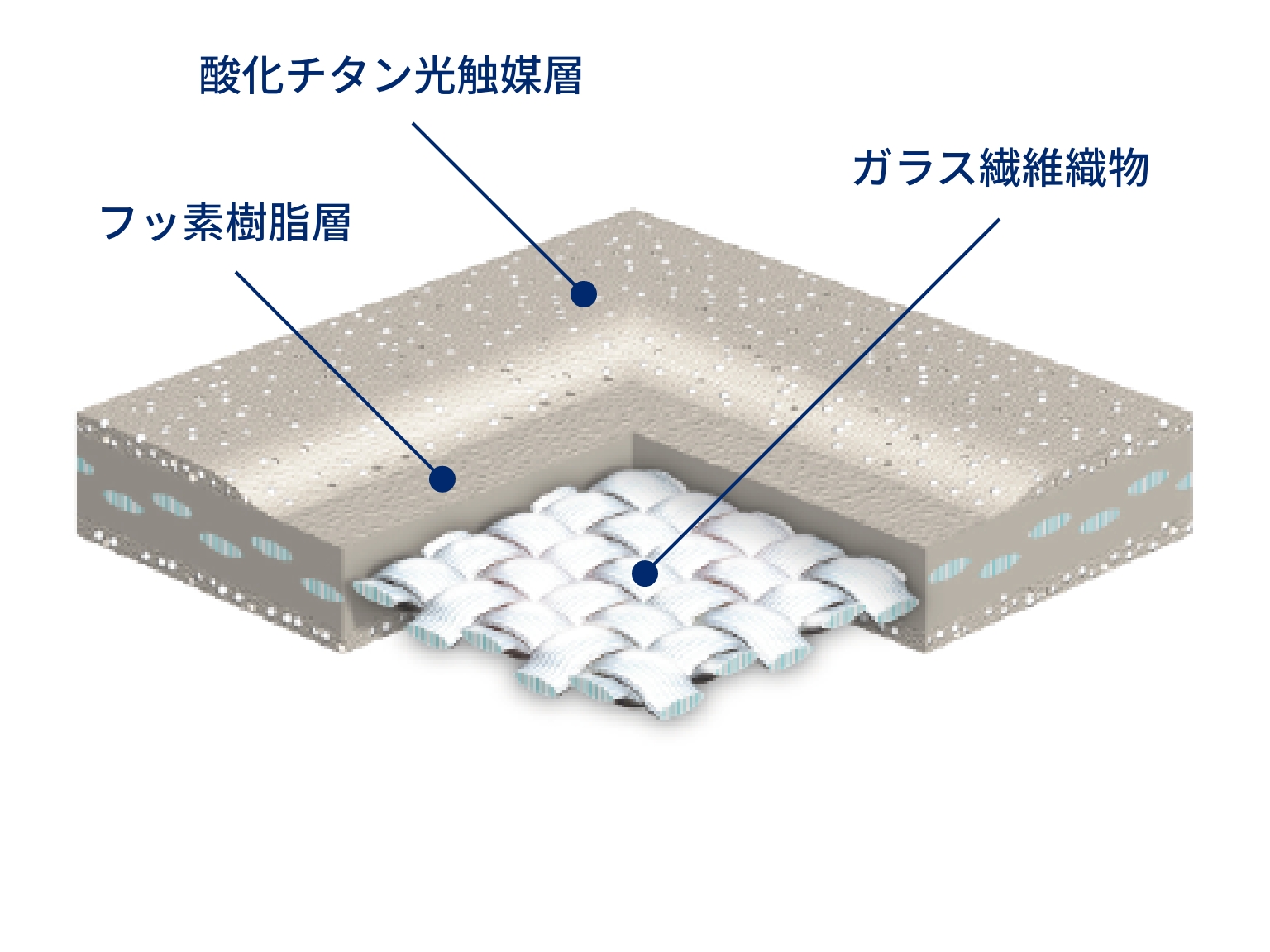

Fluoropolymer/Glass fiber membrane material

(Class A membrane material)

Membrane material made of glass fiber coated with fluorocarbon resin. This noncombustible material is expected to be durable for 30 years or more. With the advent of this membrane material, the premise that tents = temporary construction has been overturned, and membrane materials are now used for permanent buildings.

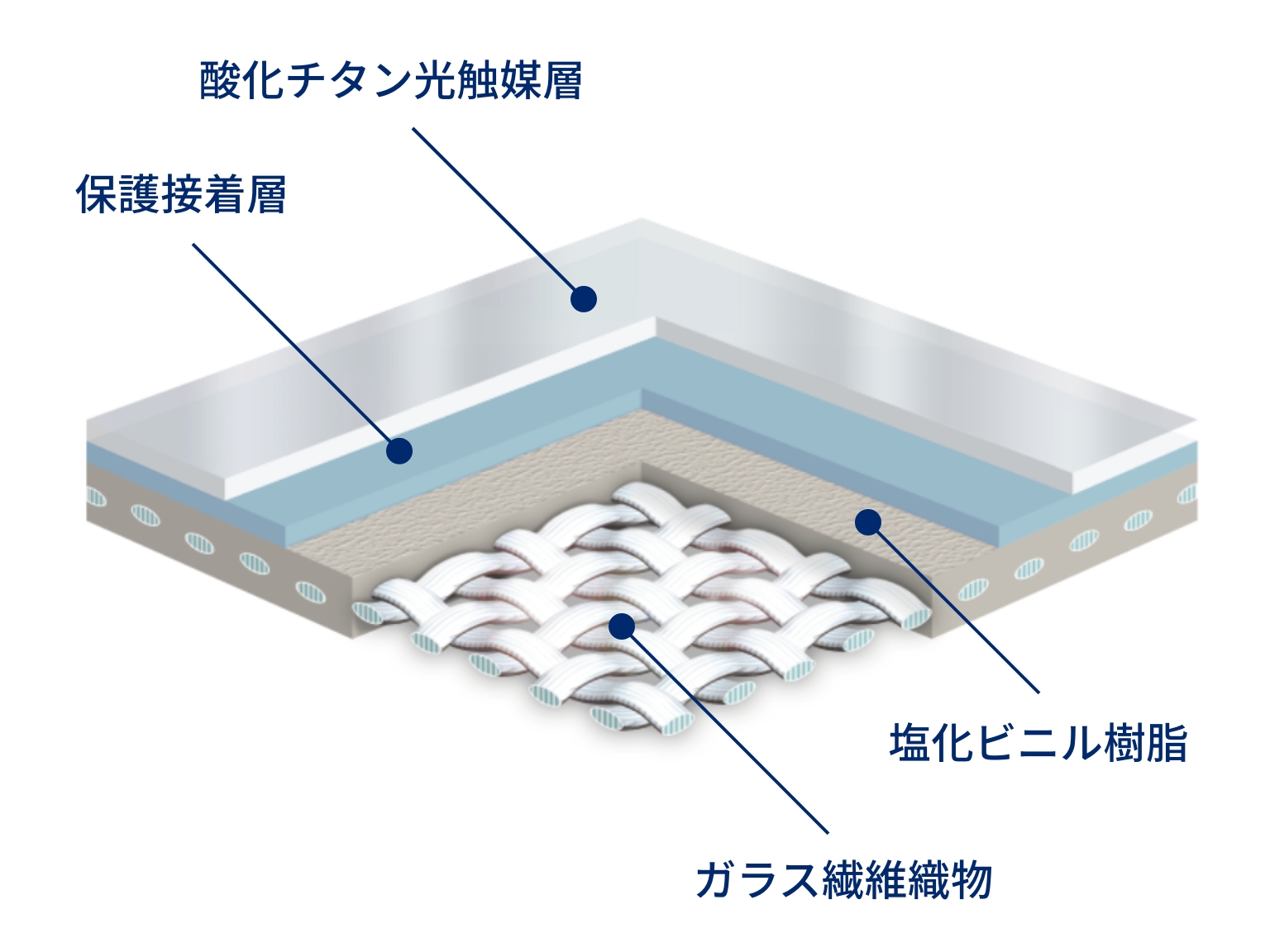

PVC/Glass fiber membrane material (Class B membrane material)

A membrane material consisting of glass fiber coated with PVC (polyvinyl chloride resin). By using glass fiber as the base fabric, fire resistance and strength are increased. Durability is about 15 years. It is a certified noncombustible material and can be used in construction for a variety of applications.

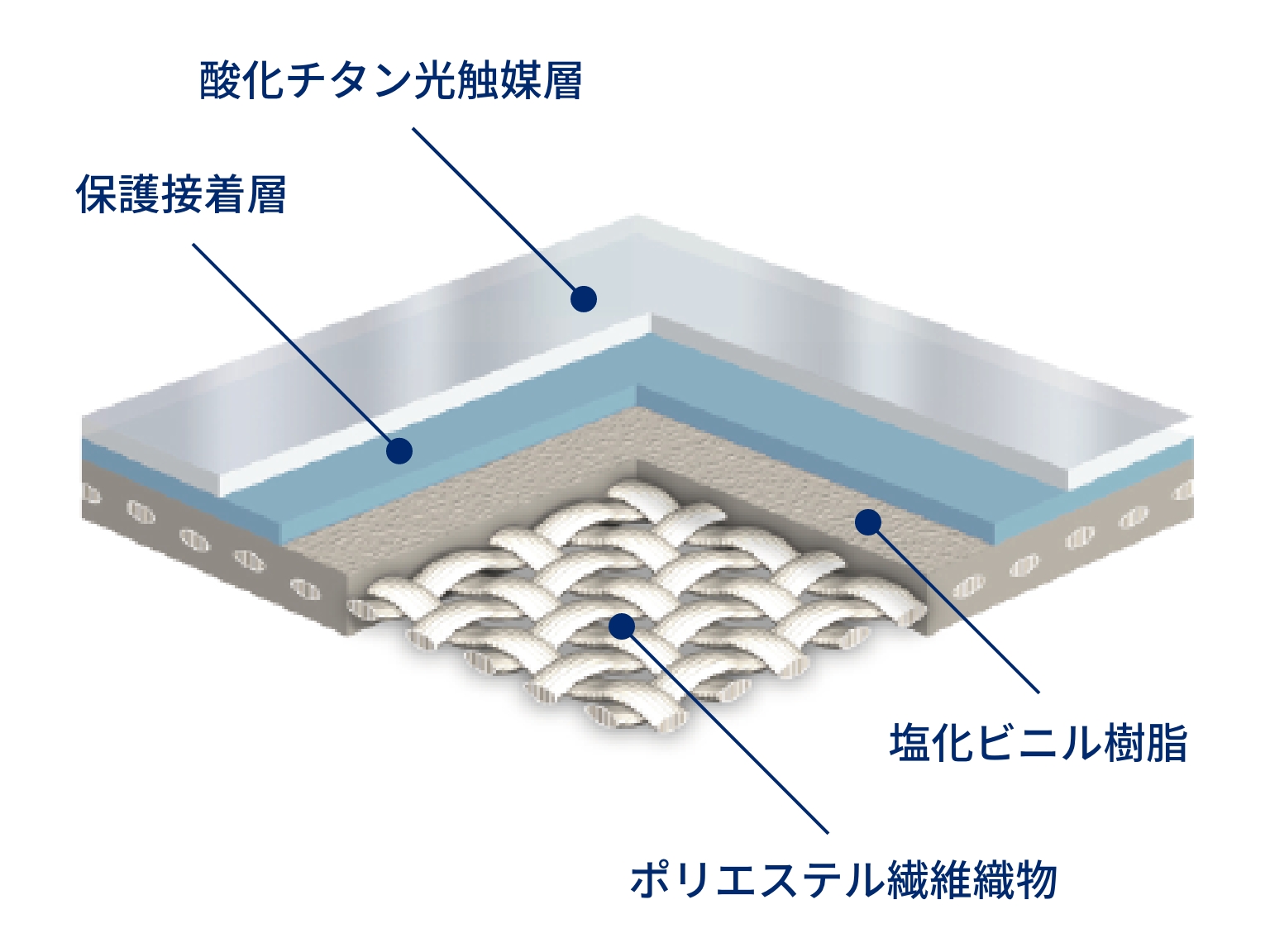

PVC/Synthetic fiber membrane material (Class C membrane material)

Membrane material made of synthetic fibers such as polyester fiber coated with PVC (polyvinyl chloride resin). Durability is about 15 years. Class 2 product for disaster prevention. Can be used in Article 22 areas of the Building Standard Law, depending on the application.

Film for membrane structure (ETFE film)

A film for membrane structures made of fluoropolymer ETFE molded into a film shape. It has no base fabric and high transparency like glass. Durability is expected to exceed 20 years, and it is a Class 1 flameproof product. In terms of fire resistance, it can currently be handled in the same manner as Class C membrane materials.

3 types of technology for architectural membrane materials

Tetrafluoroethylene resin coated film (PTFE film)

Membrane material made of glass fiber coated with fluorocarbon resin. This noncombustible material is expected to be durable for 30 years or more. With the advent of this membrane material, the premise that tents = temporary construction has been overturned, and membrane materials are now used for permanent buildings.

Photocatalytic tent (titanium dioxide photocatalytic membrane material)

A membrane material consisting of glass fiber coated with PVC (polyvinyl chloride resin). By using glass fiber as the base fabric, fire resistance and strength are increased. Durability is about 15 years. It is a certified noncombustible material and can be used in construction for a variety of applications.

High-performance fluoropolymer ETFE film

A film for membrane structures made of fluoropolymer ETFE molded into a film shape. It has no base fabric and high transparency like glass. Durability is expected to exceed 20 years, and it is a Class 1 flameproof product. In terms of fire resistance, it can currently be handled in the same manner as Class C membrane materials.

- TOP>

- Business & Products>

- Features of Membrane Structural Buildings