Renewal of aging roof to light-rich, bright, stain-resistant membrane material.

2022.09.22

Established a new method for replacing the slate roofing of passenger upper cabin, applying the same technology used for the Takanawa Gateway Station; joint patent application pending with JR East.

September 22, 2022

Taiyo Kogyo Corporation

(Tokyo headquarters: Setagaya-ku, Tokyo; Osaka headquarters: Yodogawa-ku, Osaka; President: Yumi Nomura; hereafter “Taiyo Kogyo”), a company involved in large-scale membrane structures (tent structures) and civil engineering and logistics materials, has established a new method for replacing slate roofs on passenger cabins in collaboration with East Japan Railway Company (hereafter “JR East”). Ltd. and East Japan Railway Co.

Slate roofs, which are widely used in passenger houses in Japan, need to be replaced to prevent damage and scattering. The new method allows the existing frames to be utilized as they are, significantly shortening the construction period, while replacing the roof with a lightweight, highly safe membrane roof.

Since last year, we have been verifying the effectiveness of the new construction method with JR East for a portion of the Ichigaya Station Passenger House, and the method has been adopted for the unrenovated portion of the Ichigaya Station. Furthermore, JR East’s Ueno Station is scheduled to be reroofed using the same method. In conjunction with the establishment of the technology, we filed a joint patent application with JR East and made a presentation on the construction method at the 2022 Annual Conference of the Architectural Institute of Japan (Hokkaido) held in September 2022.

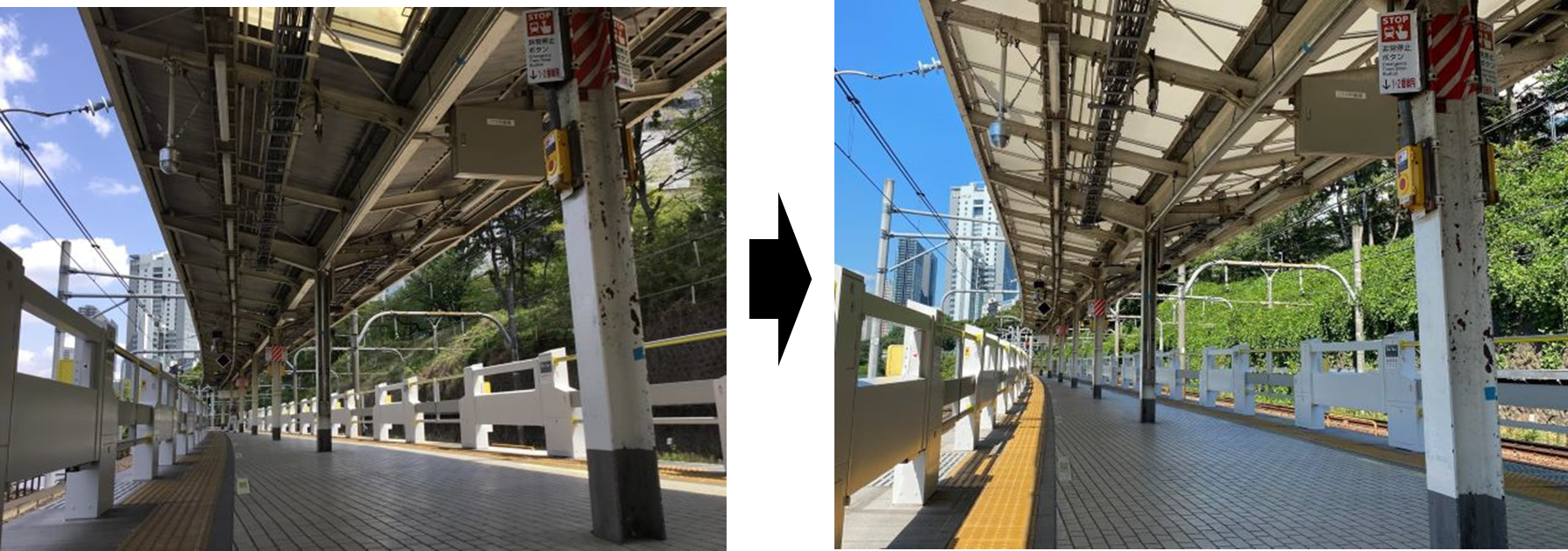

JR East Ichigaya Station, slate upper roof before replacement → straight upper roof after replacement

Since construction work on station platforms can only proceed during late-night hours when the trains are not in use, a construction method is needed to quickly proceed with a certain portion of the work in a short period of time. The new construction method is 30% more efficient than the conventional method, with a construction area of 12 to 18 m2 per day. In addition, the new method uses a new material developed by taking advantage of the characteristics of membrane materials, which have been used for the East Japan Railway Takanawa Gateway Station and the Tokyo Station Yaesu Exit Grand Roof, to create a bright, beautiful landscape with abundant lighting while having the same durability as metal roofs.

Many of the slate roofs on passenger trains in Japan are several decades old and require maintenance and re-roofing due to aging. We believe that demand for re-roofing will increase at many stations in the future, and we will begin full-scale sales expansion to major domestic railroad companies in October 2022, aiming for sales of approximately 2 billion yen over the next five years.

Taiyo Kogyo will continue to provide customers with inspiring and comfortable environments by drawing out the possibilities of membranes in the form of various ideas, without being bound by conventional concepts.

Features of the new construction method

- High work efficiency High work efficiency, capable of replacing 12 to 18 m2 per day from slate removal

- No heavy machinery required Lightweight components allow manual labor.

- No modification of existing frames is required. Existing frames can be used as they are because they are attached with adjuster hardware.

- No secondary steel frame required No fire work required as there is no extensive steel frame modification work

- Simplified design work Design work at our company based on measured data of existing frames

Advantages of Membrane Roofs

(1) Open, bright and comfortable space

The bright space of the membrane roof can greatly improve the comfort of the elderly and other customers.

(2) Effective in reducing attic temperature and preventing heat stroke

The membrane, which allows light to pass through and reflects heat, creates a comfortable space with minimal temperature increase. The high solar reflective performance has been shown to lower attic temperatures by 9°C* compared to metal roofs.

*Material manufacturer’s measurements

(3) High earthquake resistance

The membrane’s light weight reduces the load against shaking. The flexibility of the membrane also reduces the load on the columns as they follow the deformation caused by shaking. This reduces the risk of the roof falling on itself.

About Taiyo Kogyo Corporation

Taiyo Kogyo is a “leading company of membrane structures” that aims to support the safety and security of society and contribute to the realization of affluent lifestyles for people. Taking advantage of the characteristics of light and strong materials, Taiyo Kogyo is expanding its products into various construction businesses symbolized by the roofs of giant domes, as well as into civil engineering, logistics, and even the environmental field. In recent years, in particular, the company has been attracting public attention for its emergency response to the many disasters that have occurred in various regions, as well as for its medical tents used to combat the new type of coronas.

□Official HP: https://www.taiyokogyo.co.jp/