"SAM Method"

-Rockfall buffer method-

A low-cost, high-performance rockfall buffer method for use on roadway caverns.

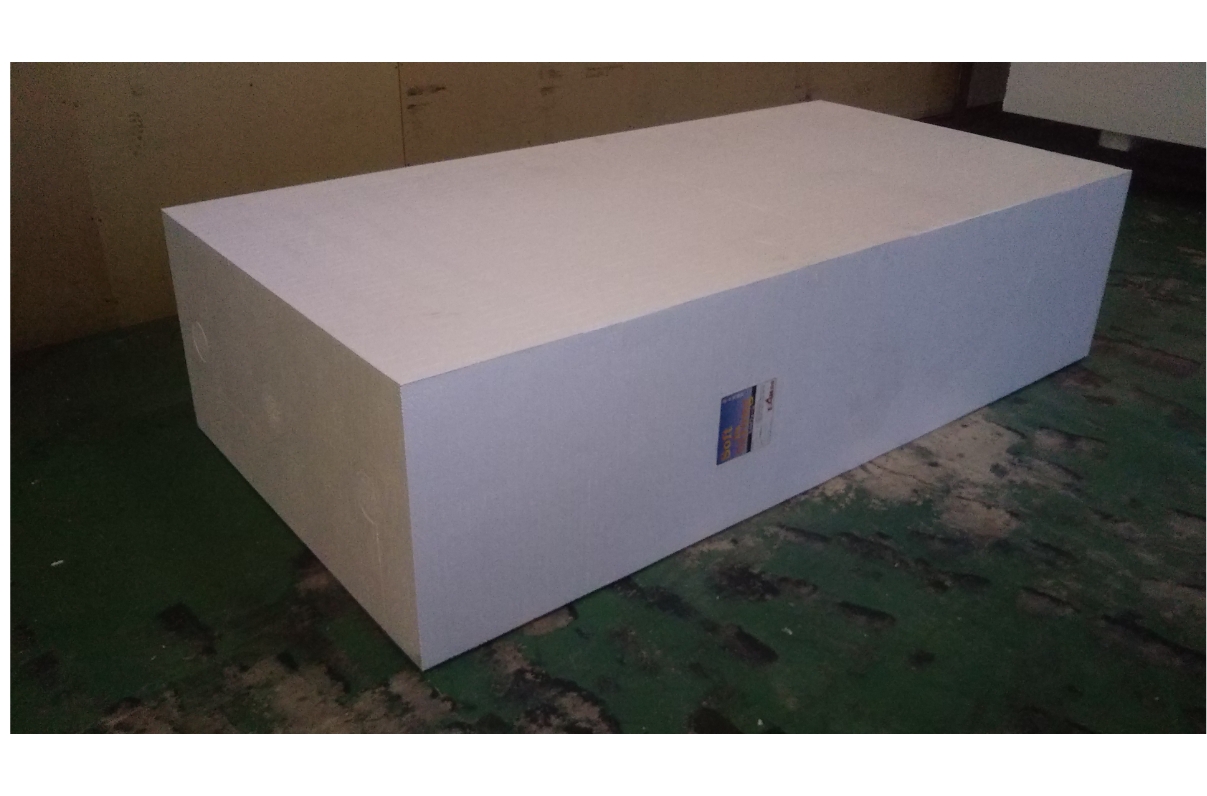

The SAM method uses lightweight Styrofoam (SAM foam) instead of sand or crushed stone, which have been used for rock sheds, to provide a more effective buffer.

New Technology Information System “NETIS Registration”: SAM Method Reinforcement Type

Registration No. KK-130016-A

*For sale only in the Japanese market.

Product & Service

Features

Buffer

The buffering effect can be expected to be 3-6 times greater than that of sand.

Lightweight

It weighs about 1/100 of earth and sand and can be easily transported by human power.

Independence

Stacking produces little or no side pressure when loads act on the top surface.

Watertightness

Extremely low water absorption over time.

There is little need to consider the effects of water, even under humid conditions.

Workability

Since it is lighter than sand and other materials, it requires little or no large construction equipment for transportation and installation, and can be done by human labor.

Main components and installation procedures

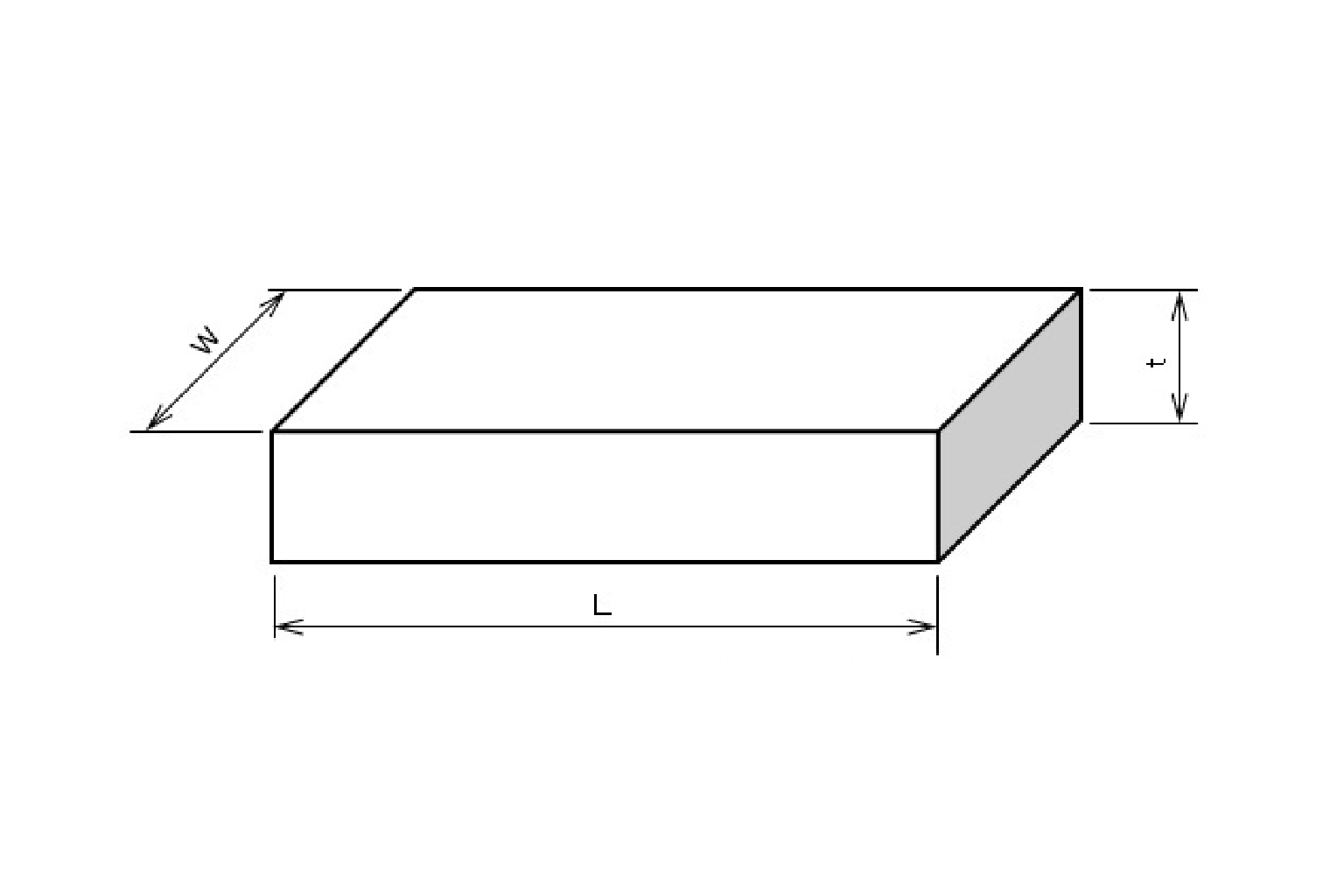

SAM Form

Shape and Dimensions

1.0m(W)×2.0m(L)×0.5m(t)

SAM Joint

Integrate laminated SAM forms with each other.

Fabric formwork “Tacom

Protect the uppermost or inclined surface of the SAM form against external injury.

Selection and planning of slope works according to the level of performance design.

| item |

test procedure | unit | type | ||

|---|---|---|---|---|---|

| SAM-15 | SAM-20 |

||||

| Density | JIS K 7222 | kg/m3 | 15/ +10% -0% | 20/ +10% -0% | |

| Compressive strength (10% strain) | JIS K 7222 | N/mm2 | 8.5 x 10-2~11.0 x 10-2 | 12 x 10-2~15.0 x 10-2 | |

| Dimensions | length | tape measure | mm | 2000±11 | |

| range (e.g. of voice) | tape measure | mm | 1000±7 | ||

| thickness | tape measure | mm | 500±4 | ||

| Flammability | JIS A 9511 | Passed flammability test | |||